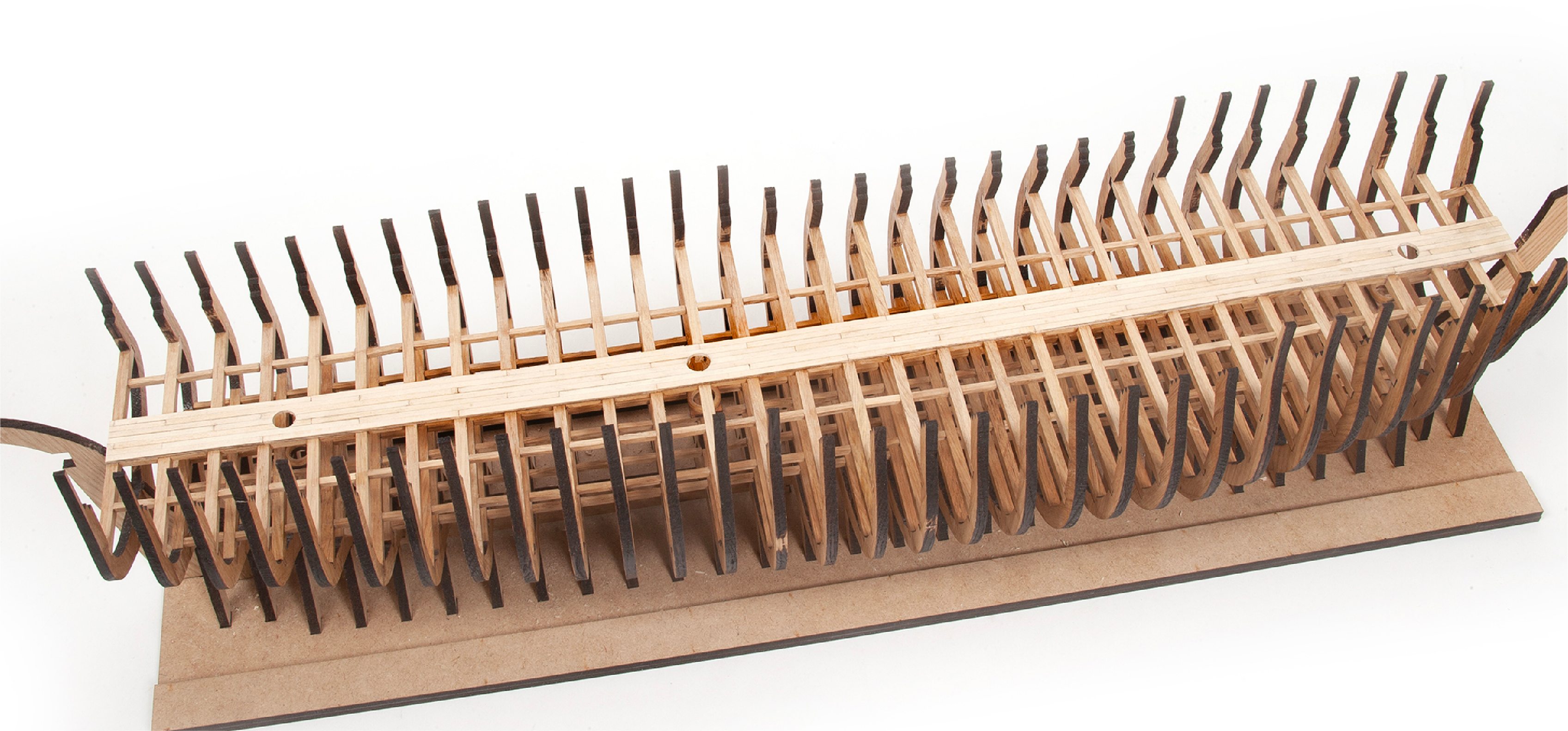

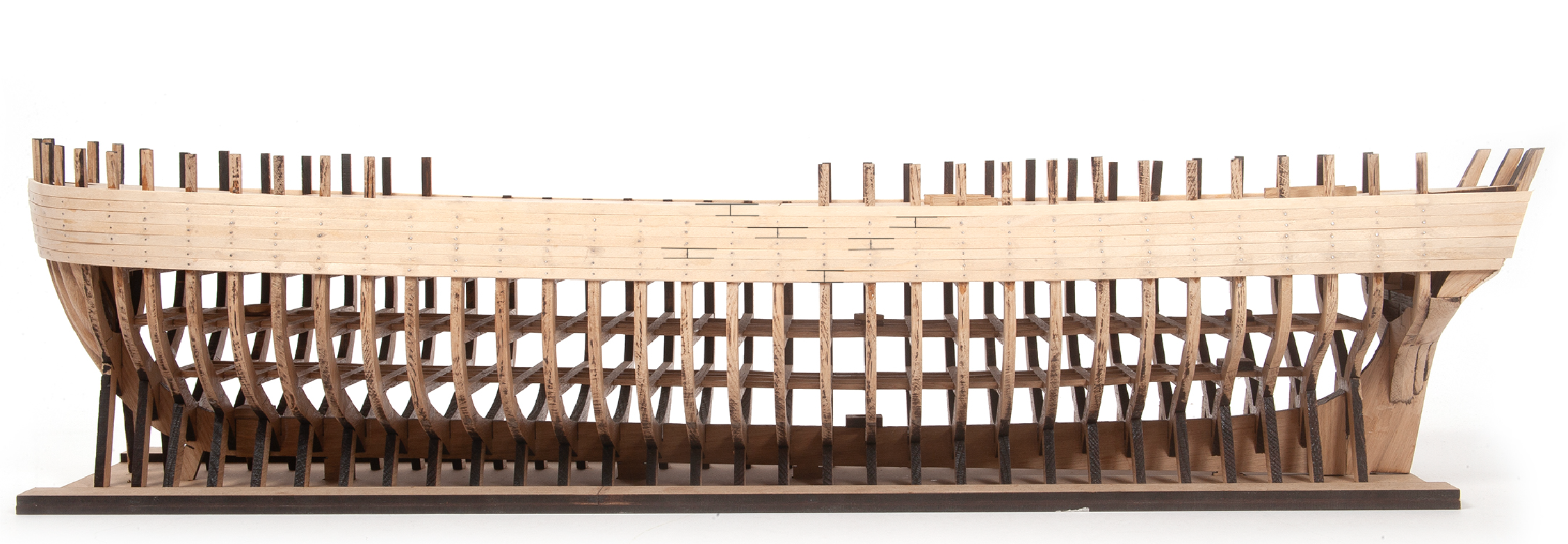

Instructions for building your USS Constitution model ship

Your model of the USS Constitution is divided into 12 packs.

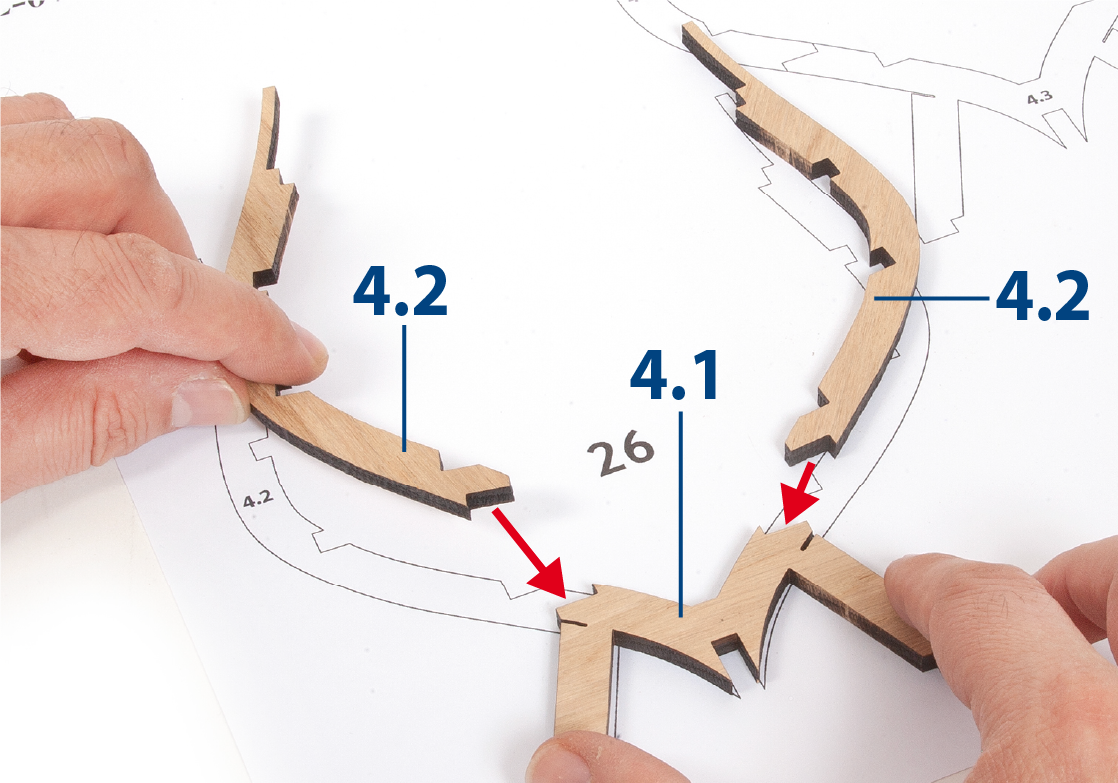

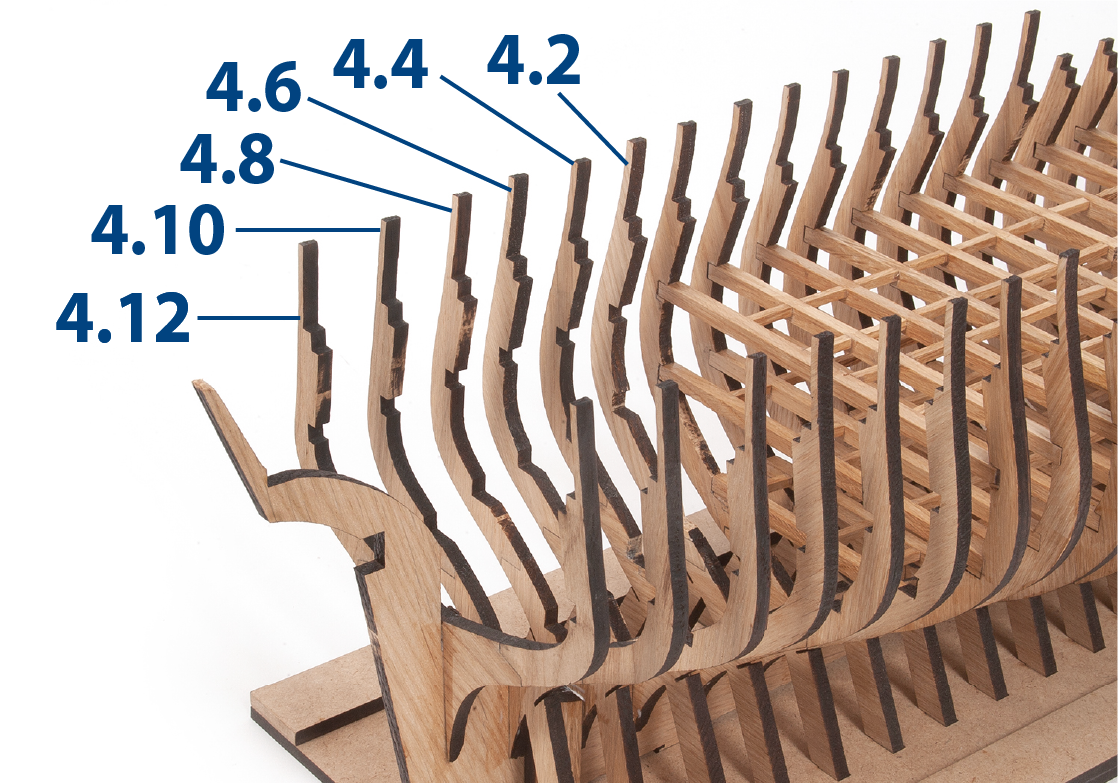

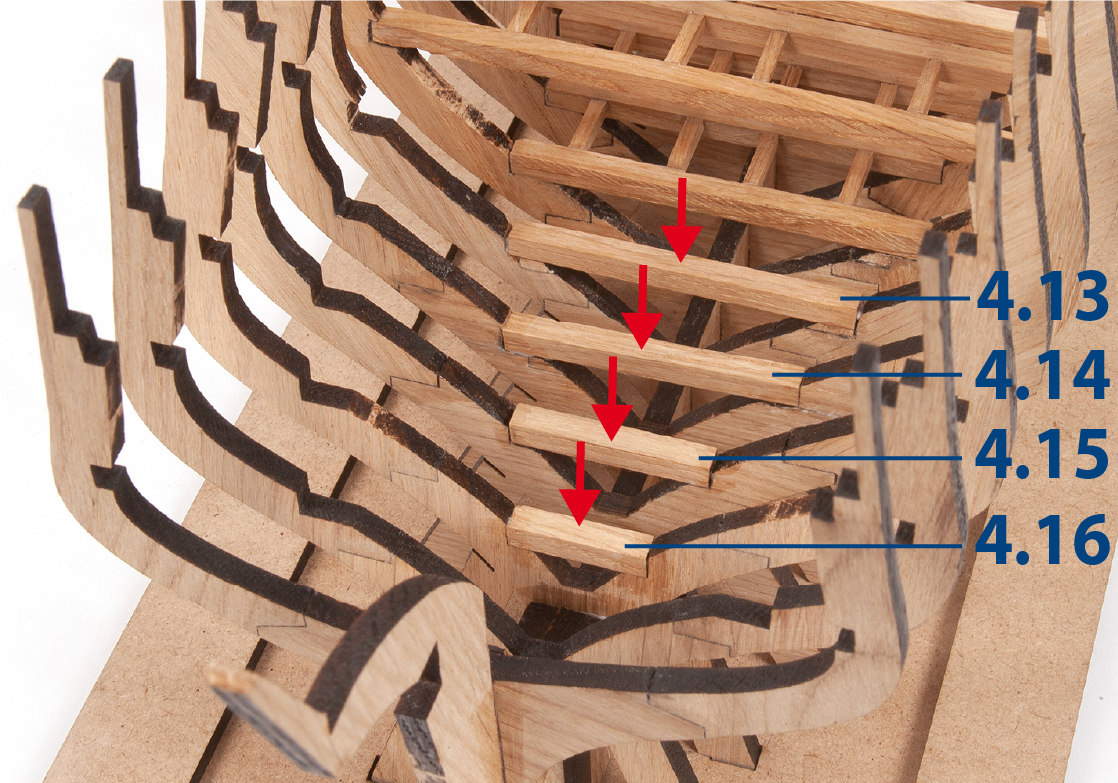

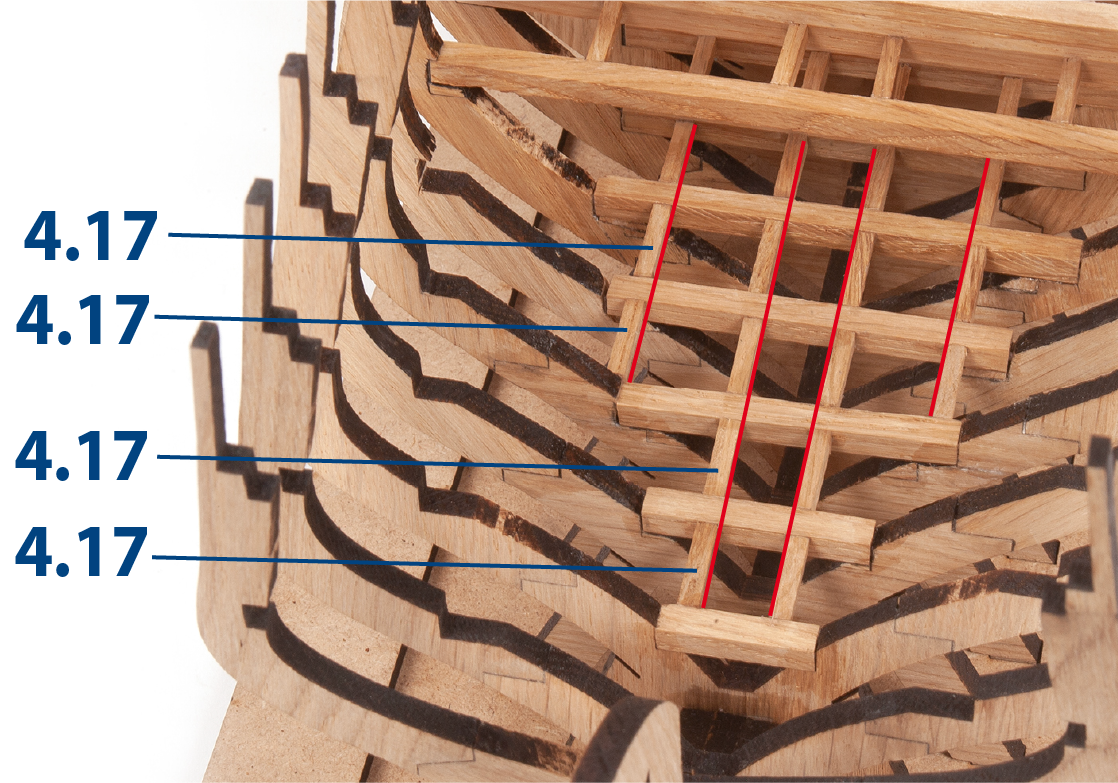

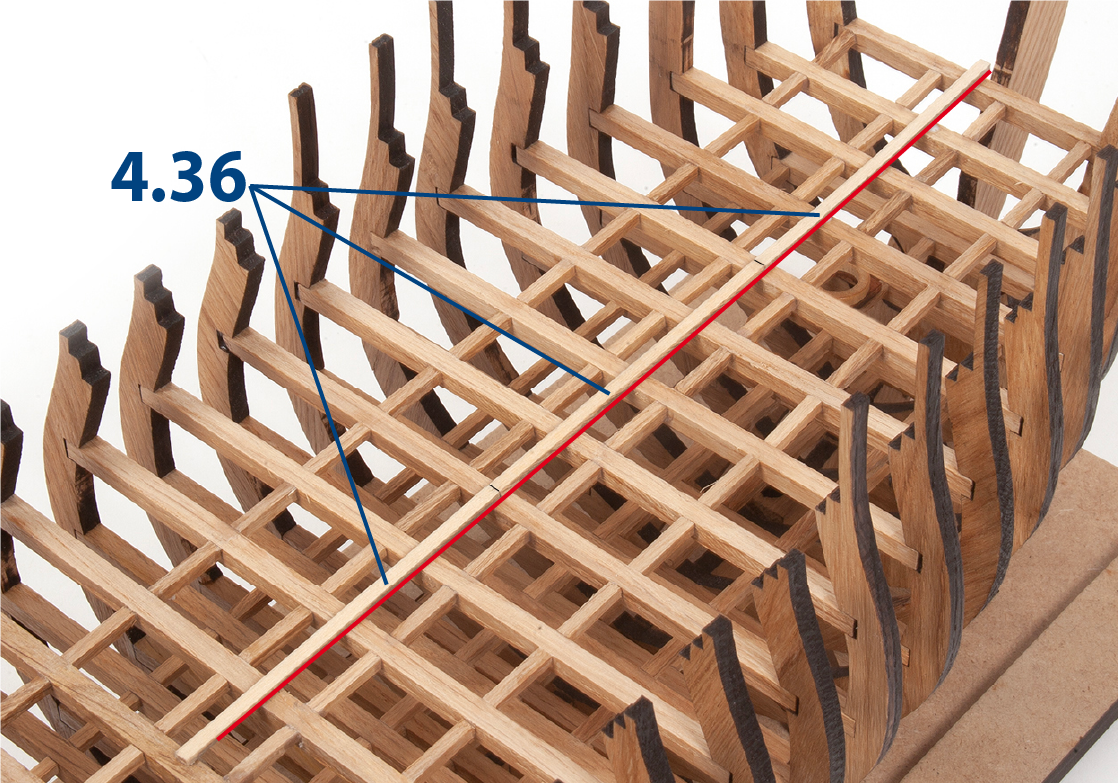

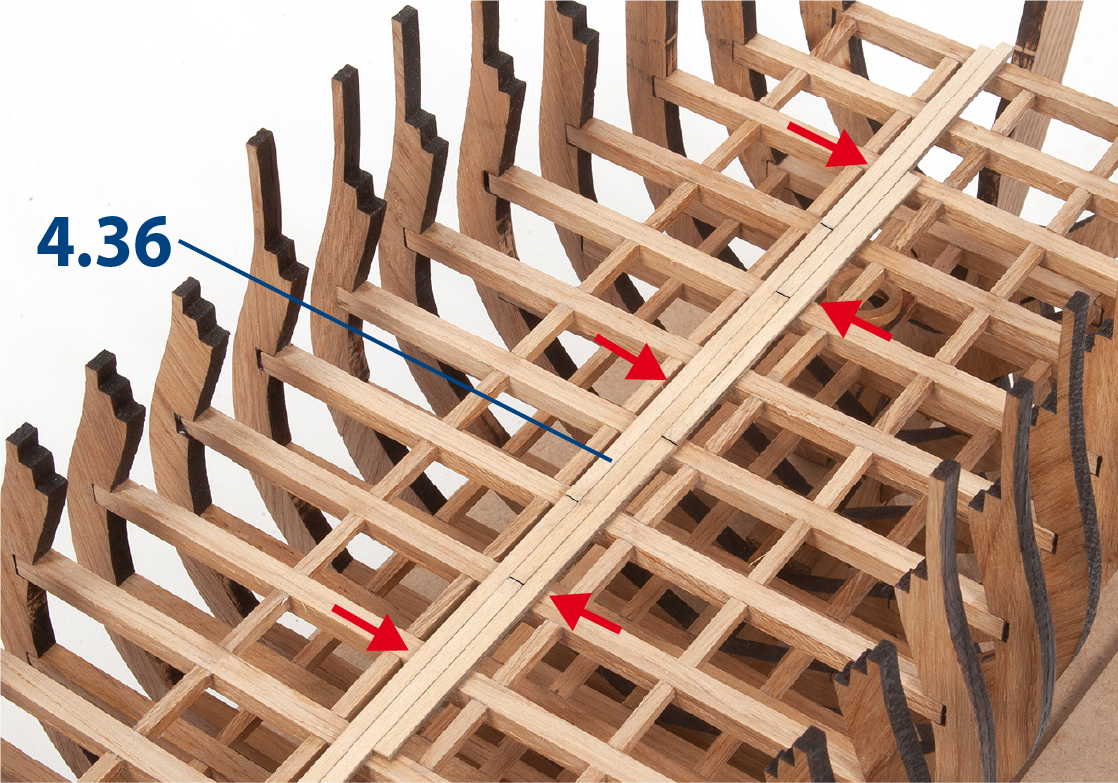

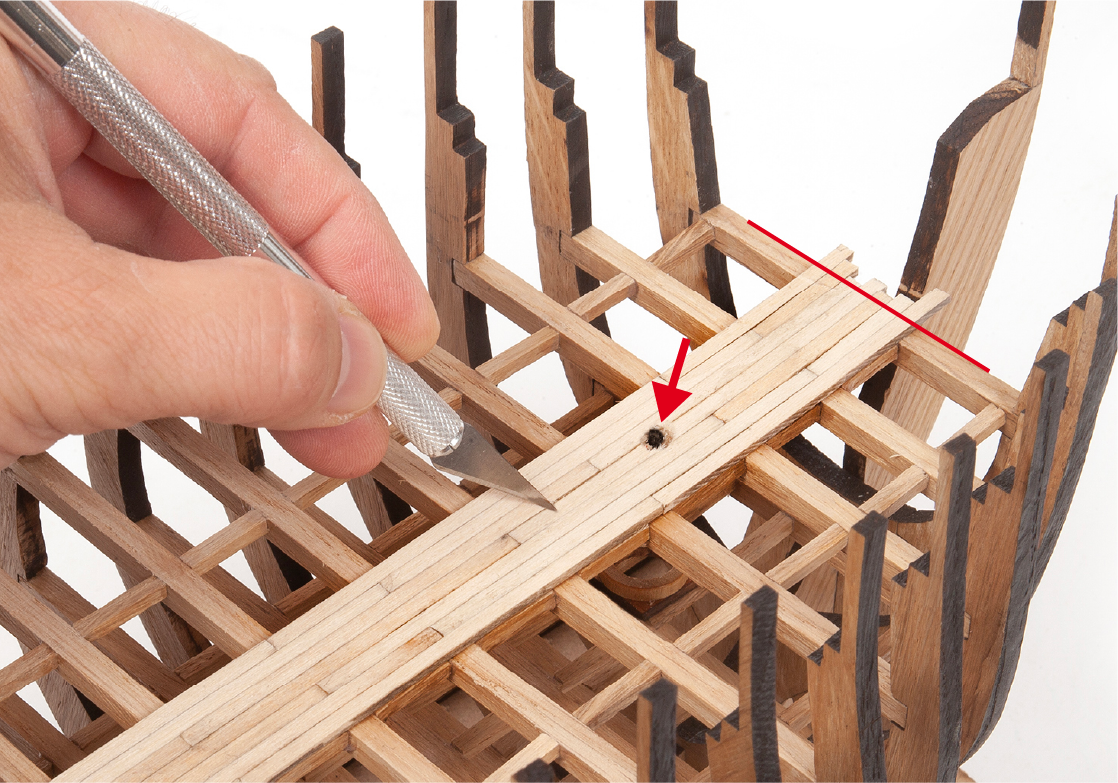

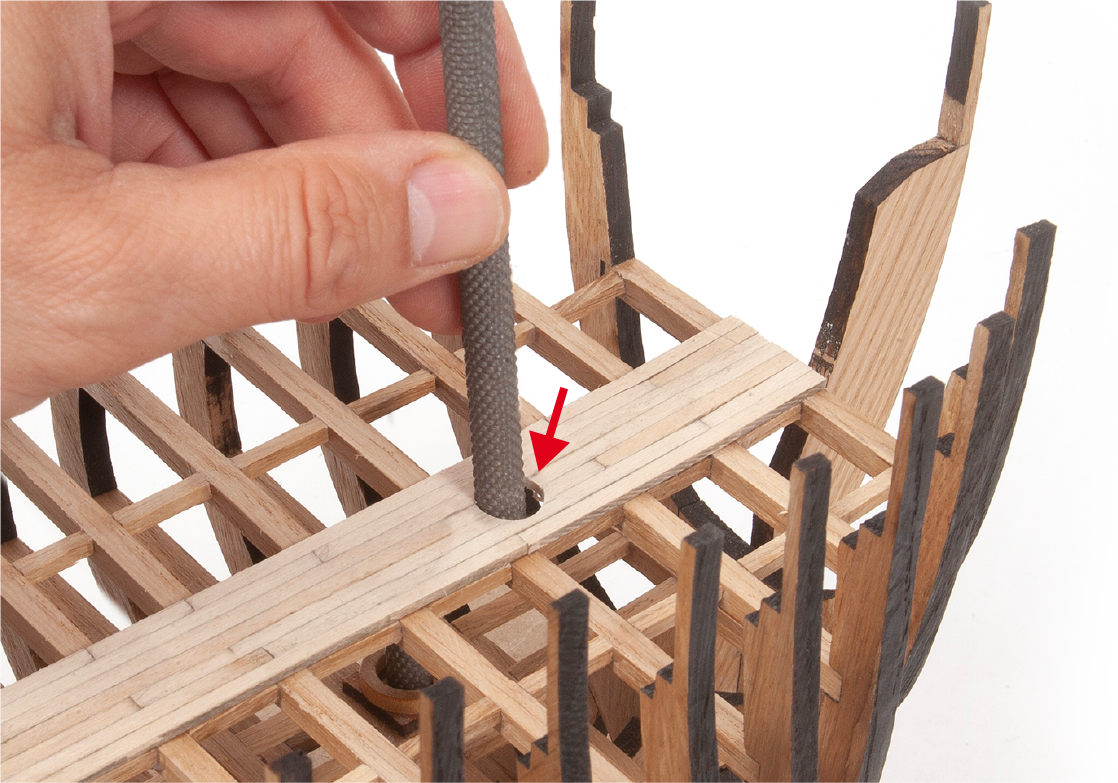

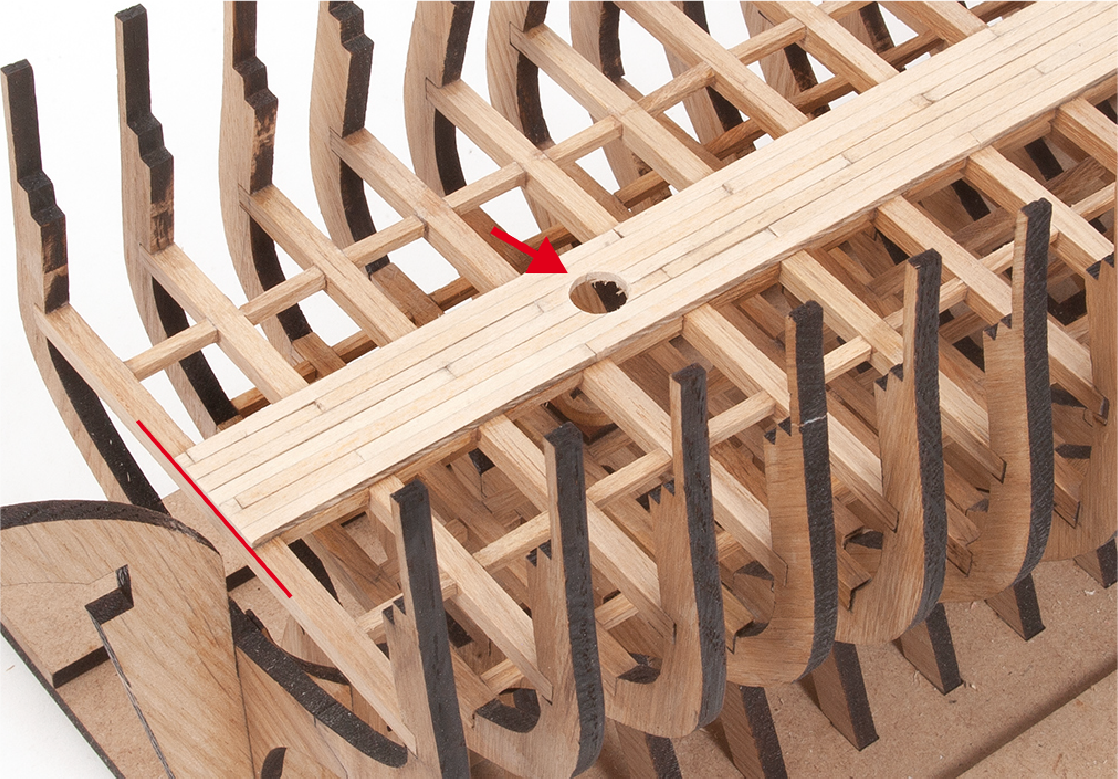

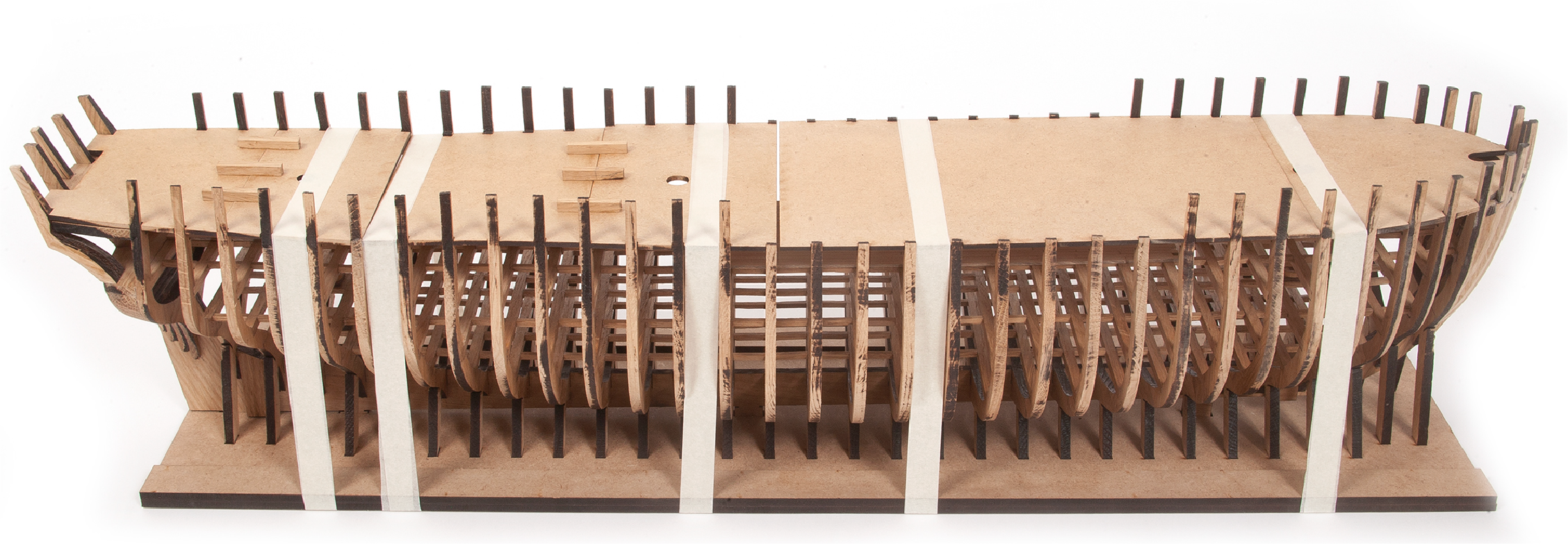

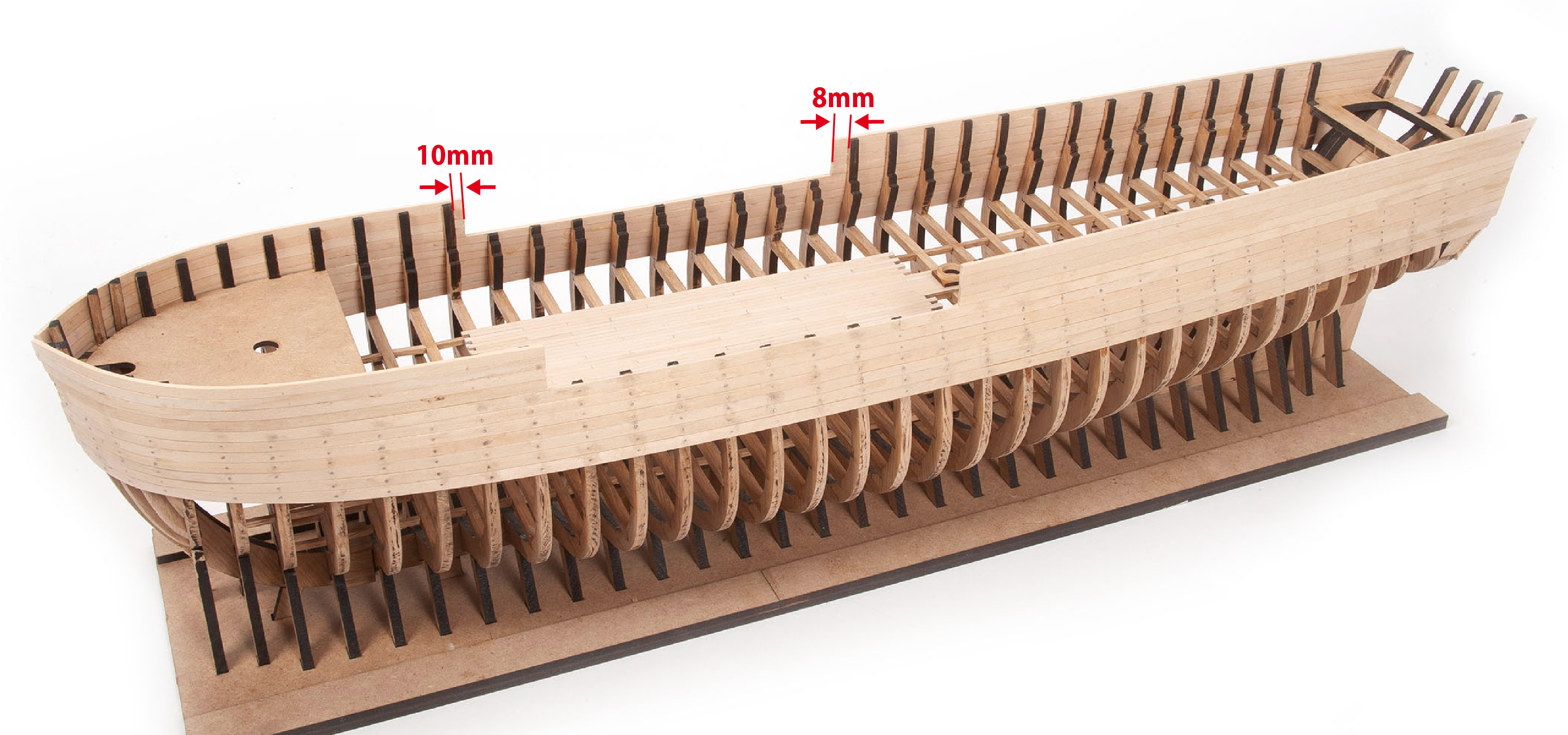

You will need to follow the step-by-step assembly photos, the plans and the explanatory texts below.

Please save the leftover materials from each pack for use when instructed to do so at a later stage of the assembly instructions.

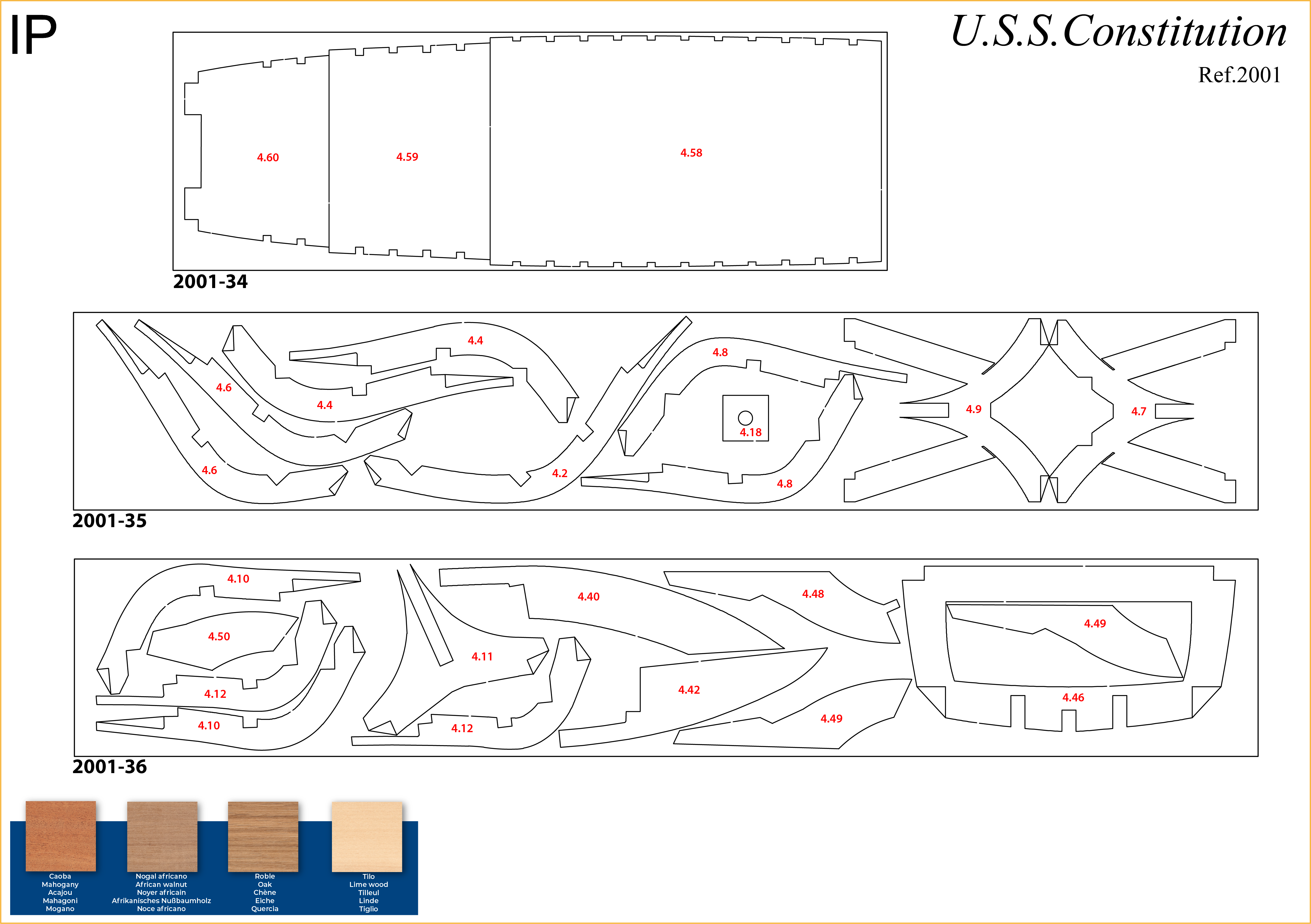

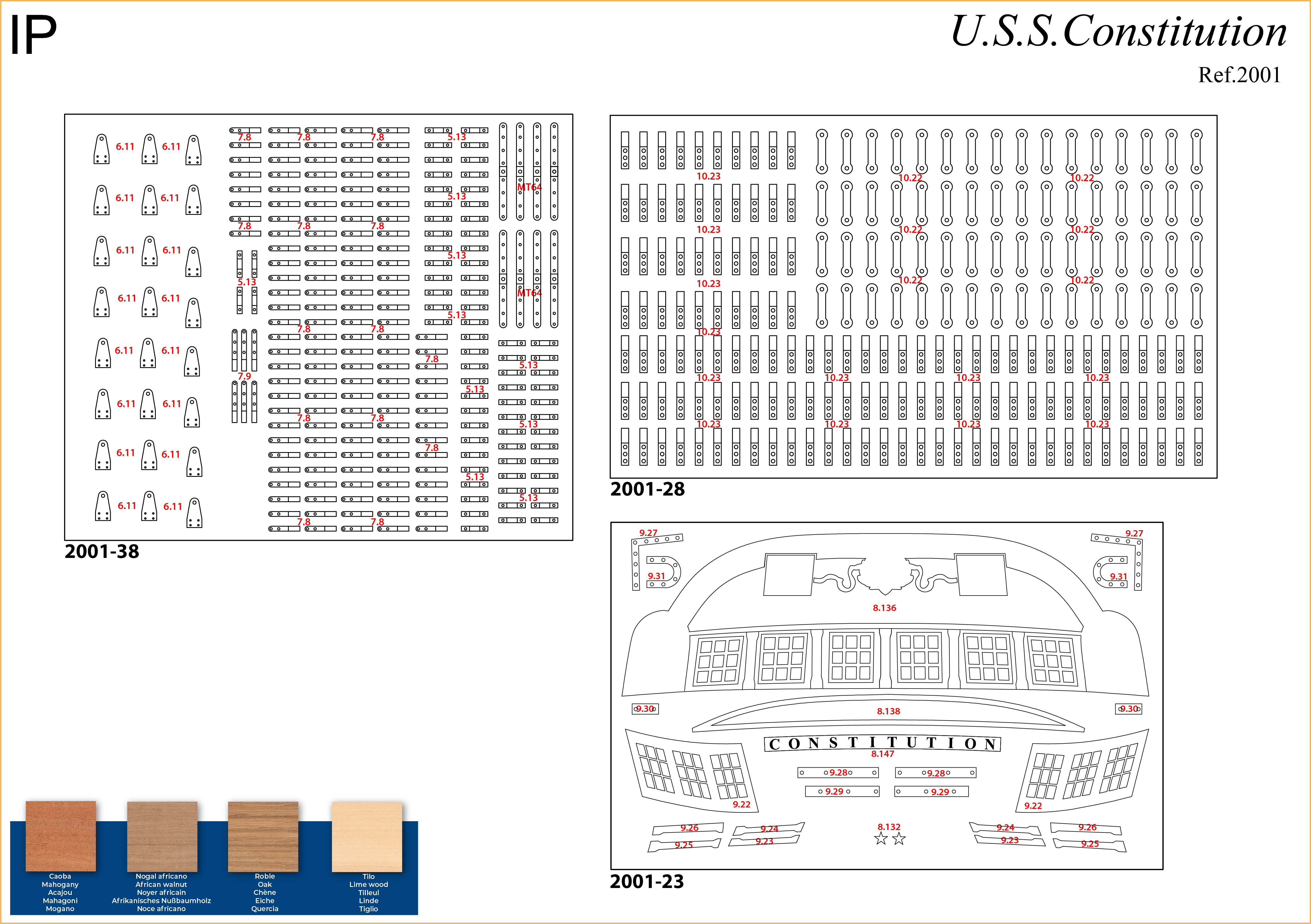

The IP sheets displayed below are drawings of laser-cut parts and photo-etched brass parts and will serve as a guide for identification of some parts.

Use the PARTS REFERENCE table to help locate the parts.

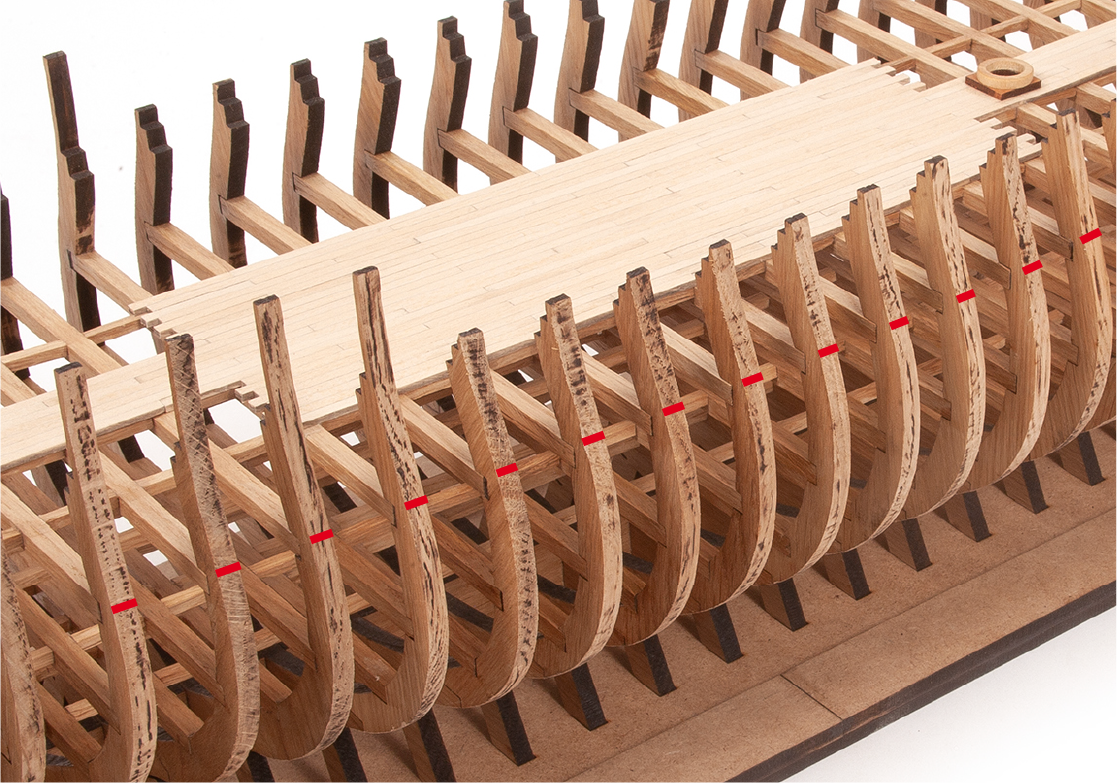

The PL-00 templates (printed at 1/1 scale) included in each pack will serve as a guide for building the frames.

Please check the list below to ensure you have all the tools required for building your wooden ship.

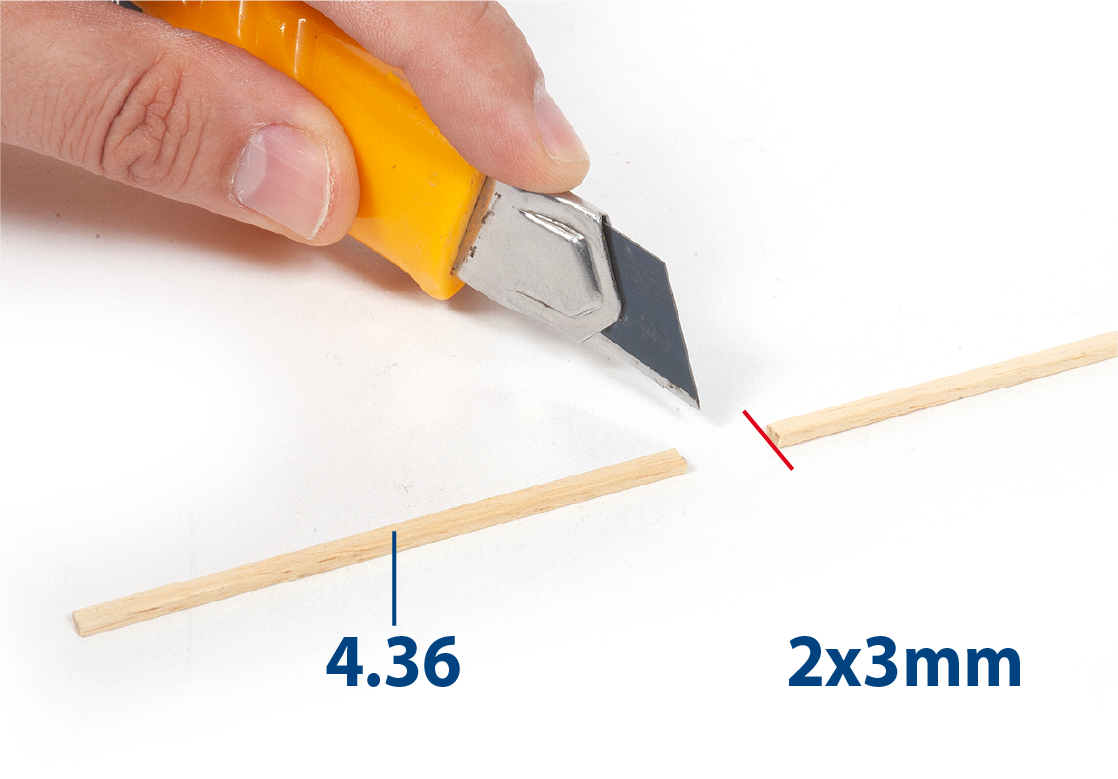

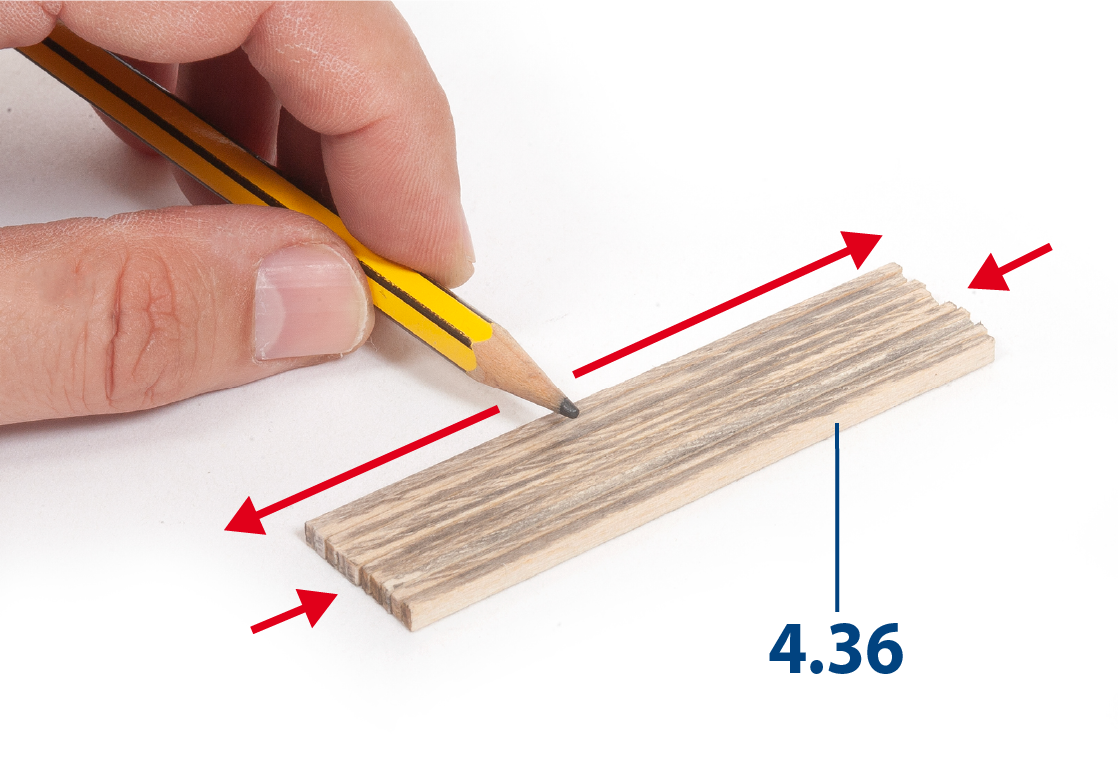

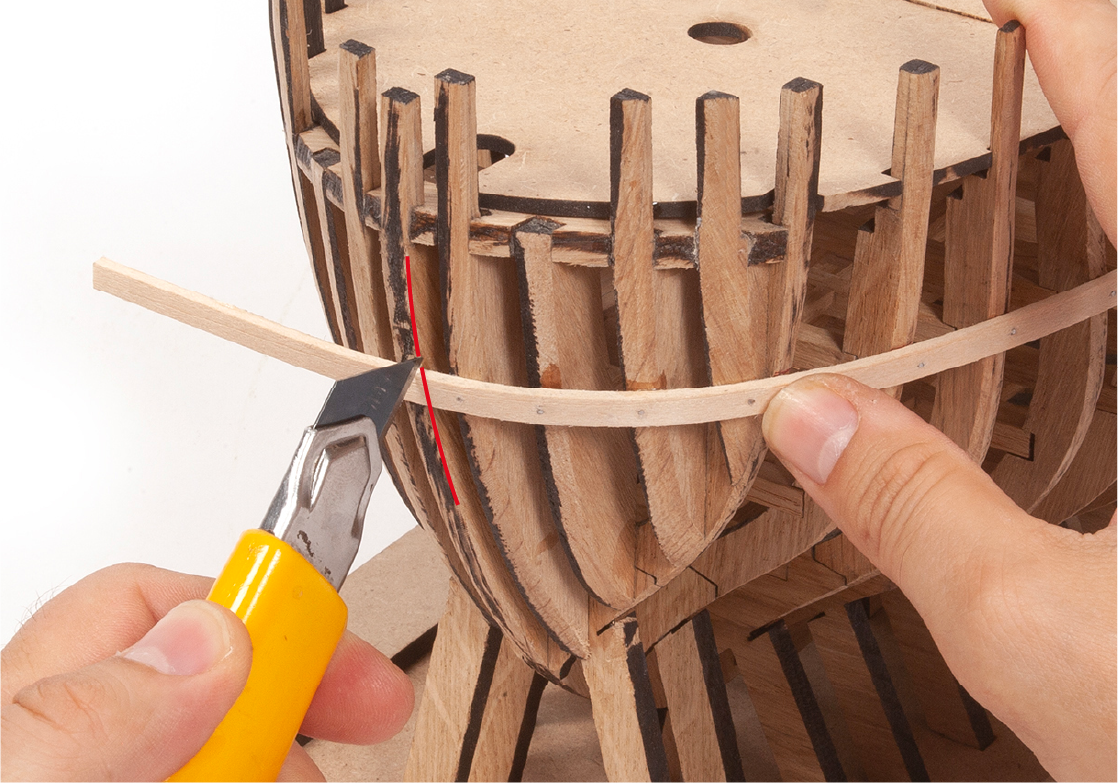

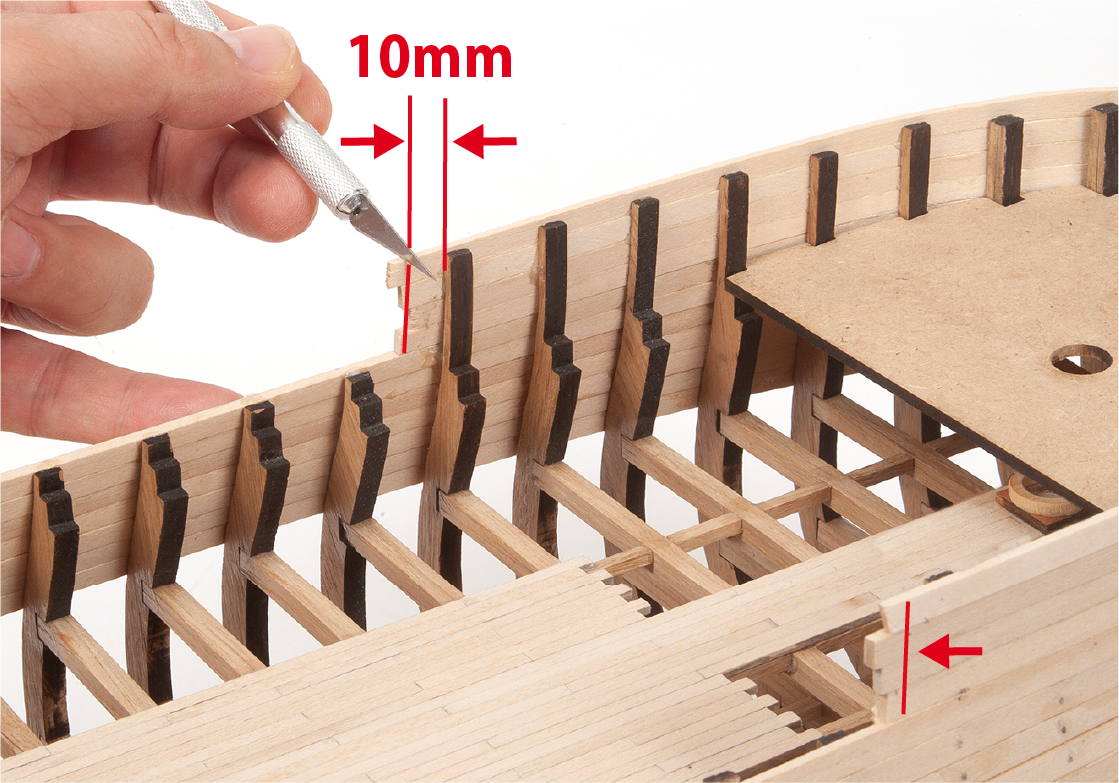

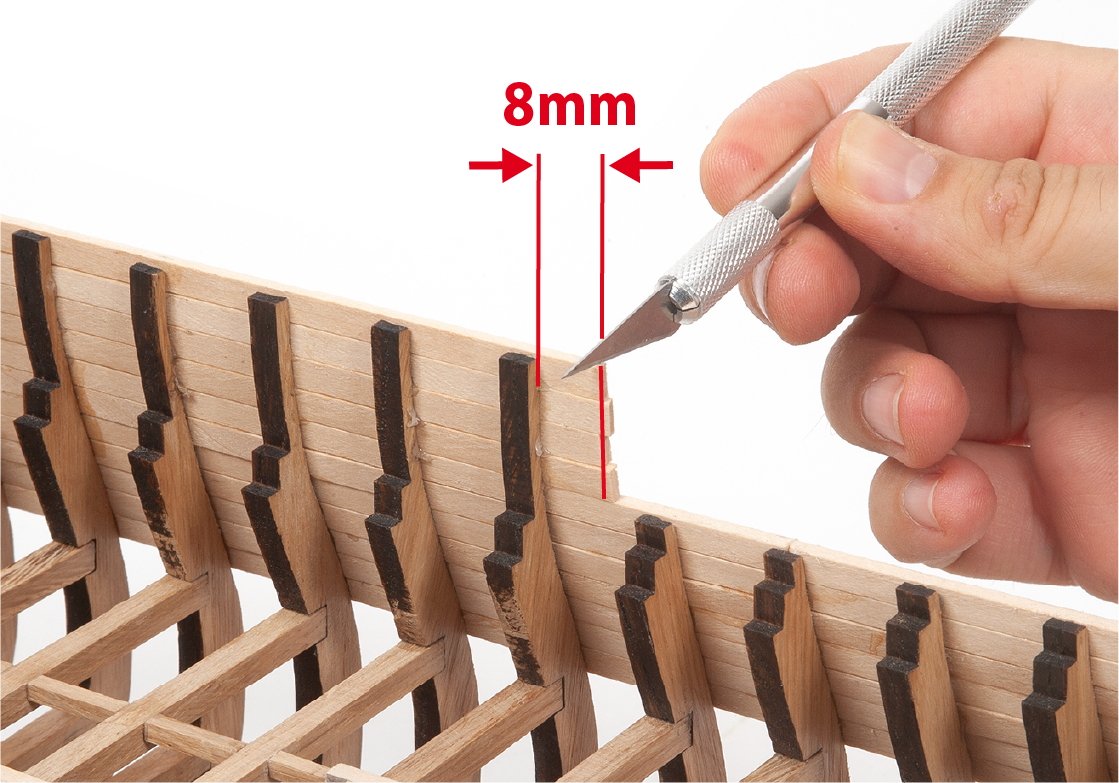

When removing a part, cut the ribs that join the part to the wooden plate with a cutter.

Remove the parts carefully so as not to break them.

Keep and store the parts in their frames. Only remove the parts you are working on in each step.

Extra support can be found on our forum or from the Expert Directory page of our website.

PARTS LIST

| Material | Quantity | |

| Boards 2001-34, 2001-35, 2001-36 | Wood | 3 |

| Sheets 2001-23, 2001-28, 2001-38 | Brass | 3 |

| Wooden Strips | ||

| 5 x 5 x 400 mm | Oak | 14 |

| 3 x 3 x 400 mm | Lime wood | 7 |

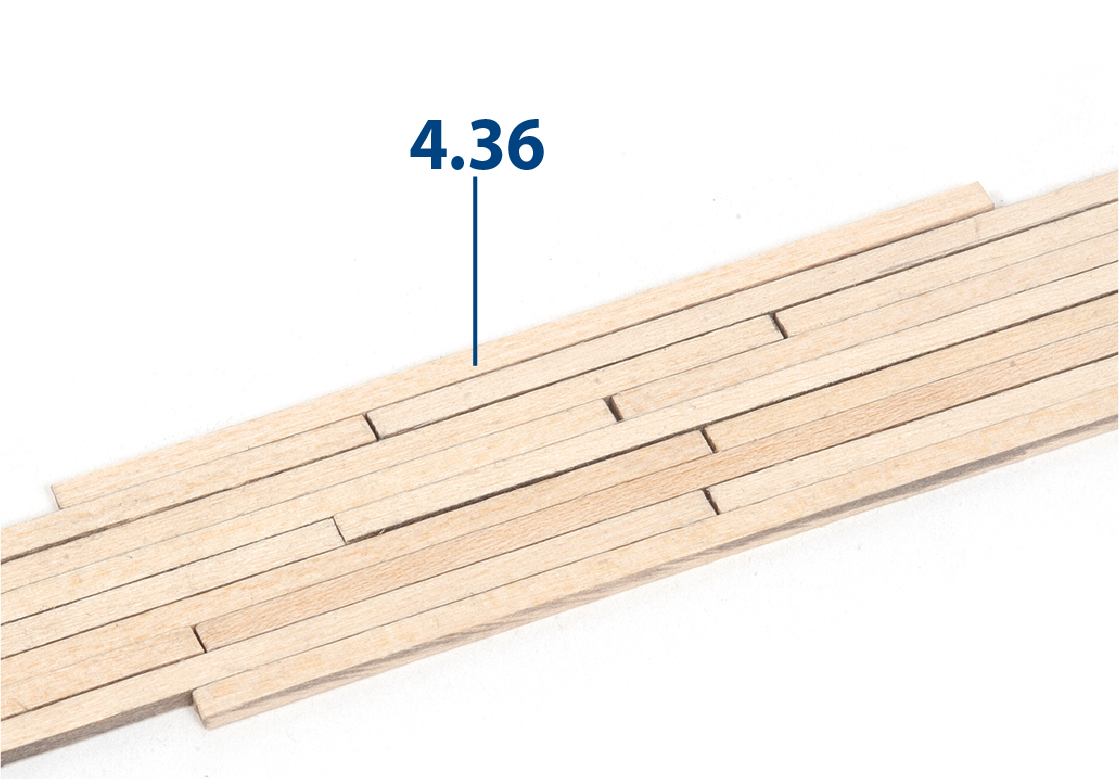

| 2 x 3 x 600 mm | Lime wood | 10 |

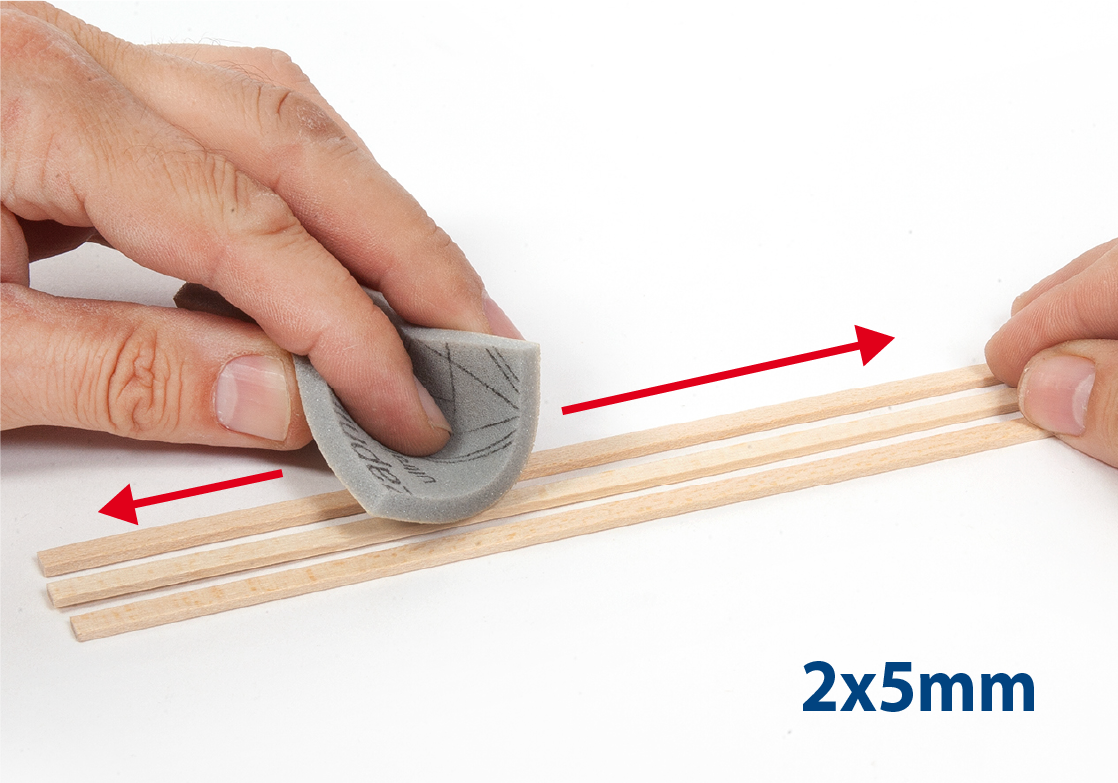

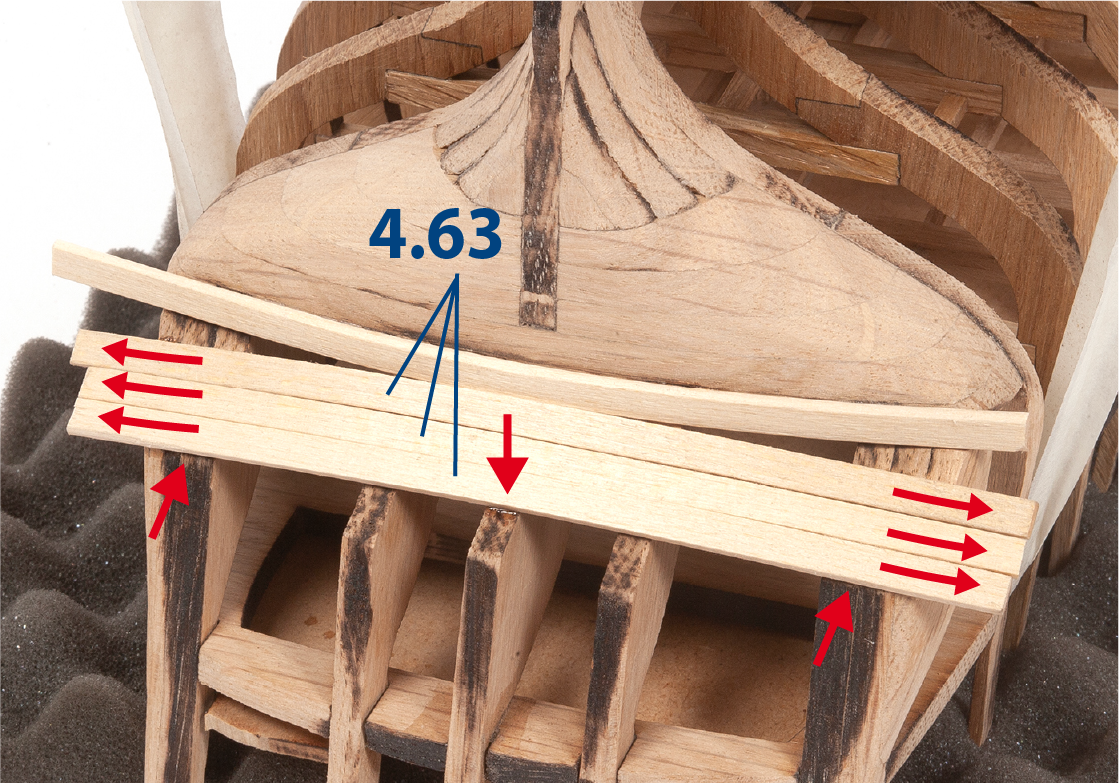

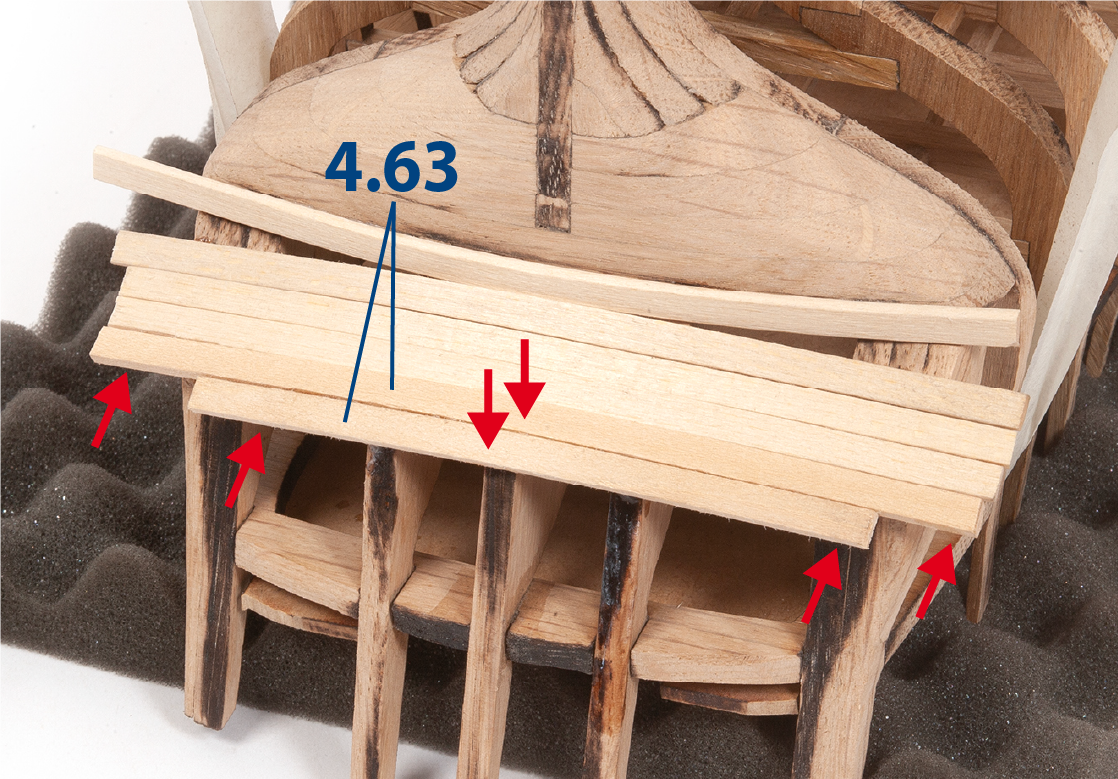

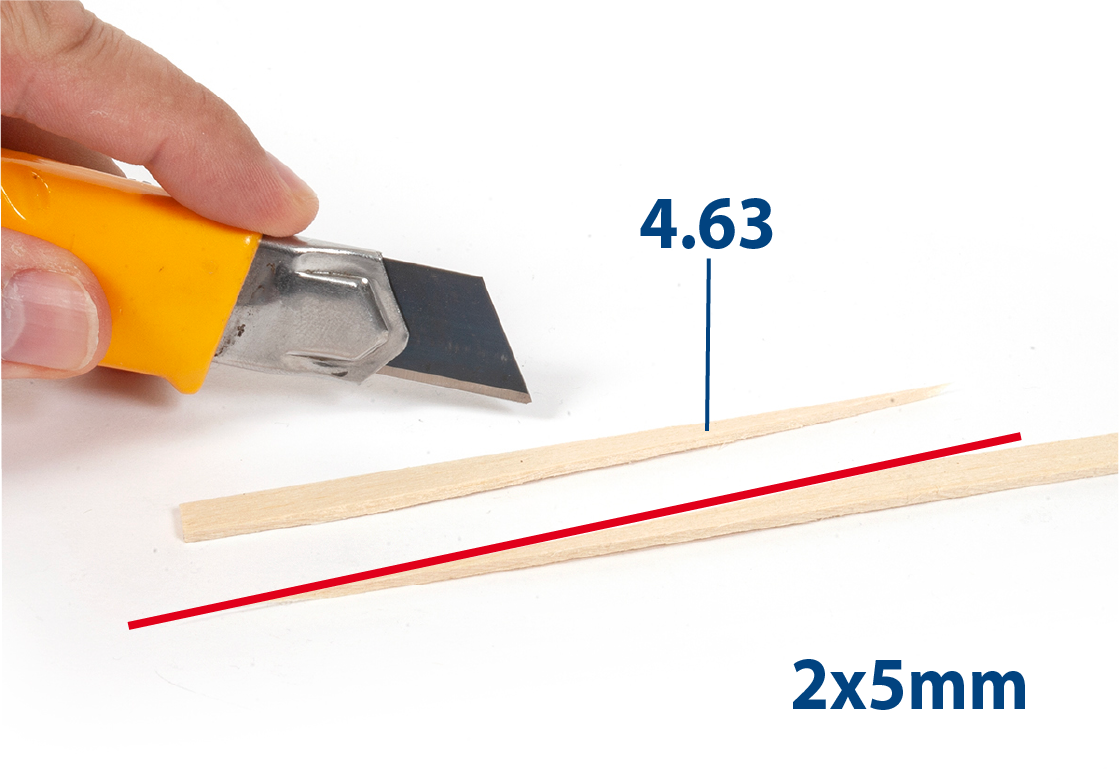

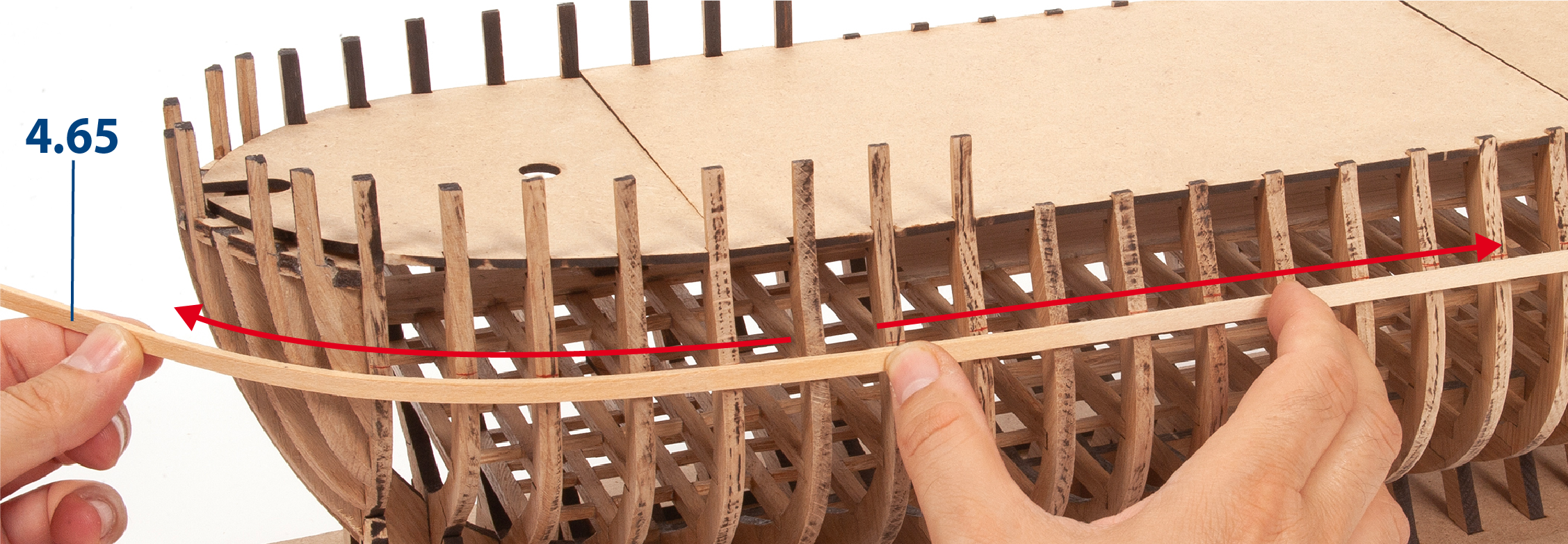

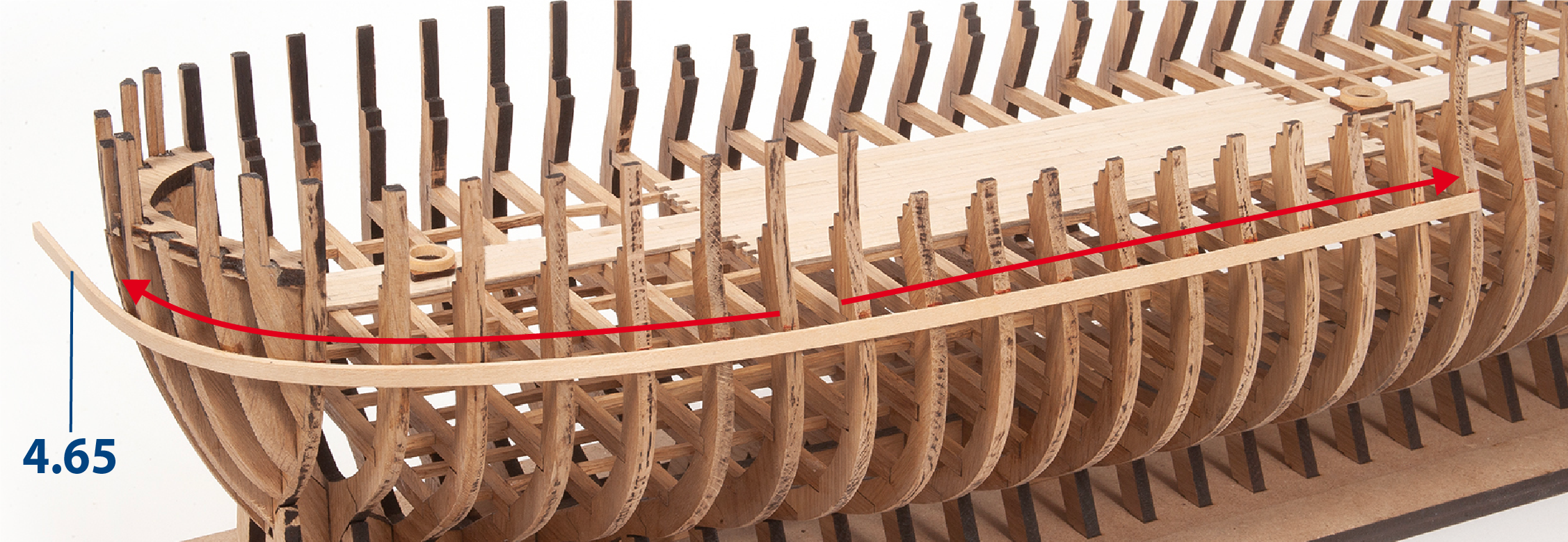

| 2 x 5 x 600 mm | Lime wood | 50 |

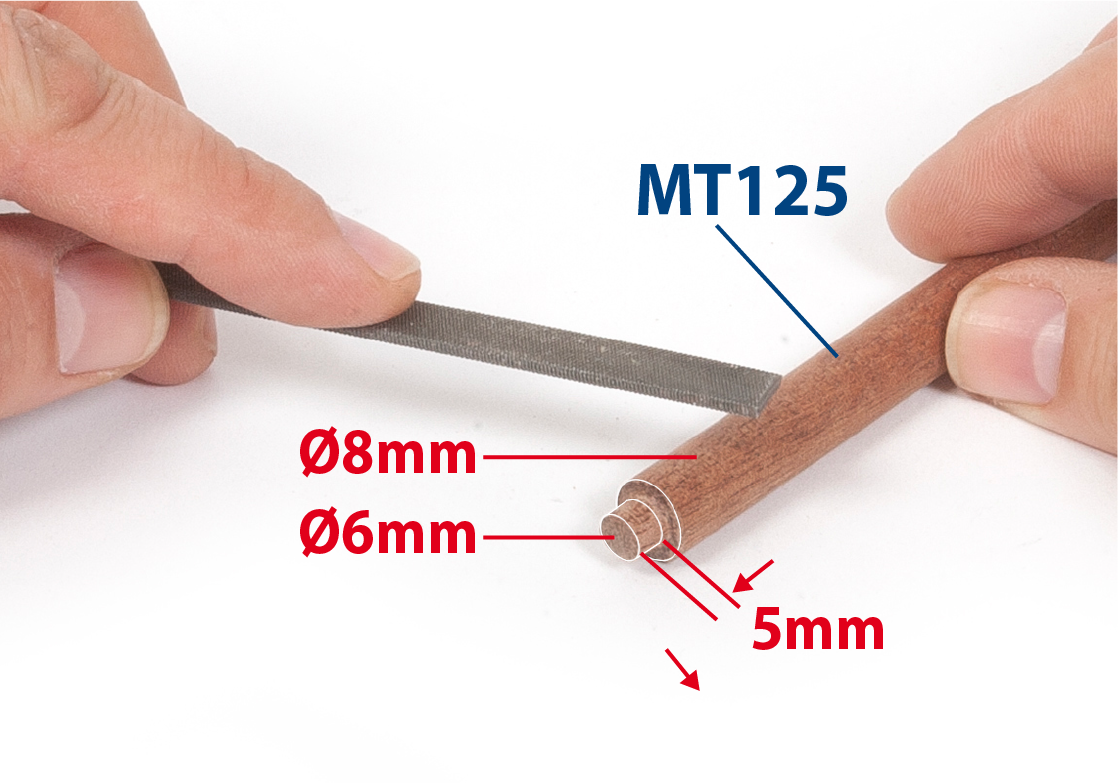

| Rod (ø 8 mm x 400 mm) | Mahogany | 1 |

| Templates | ||

| Assembly template PL-07 | 1 | |

| Assembly template PL-08 | 1 | |

| Other Parts | ||

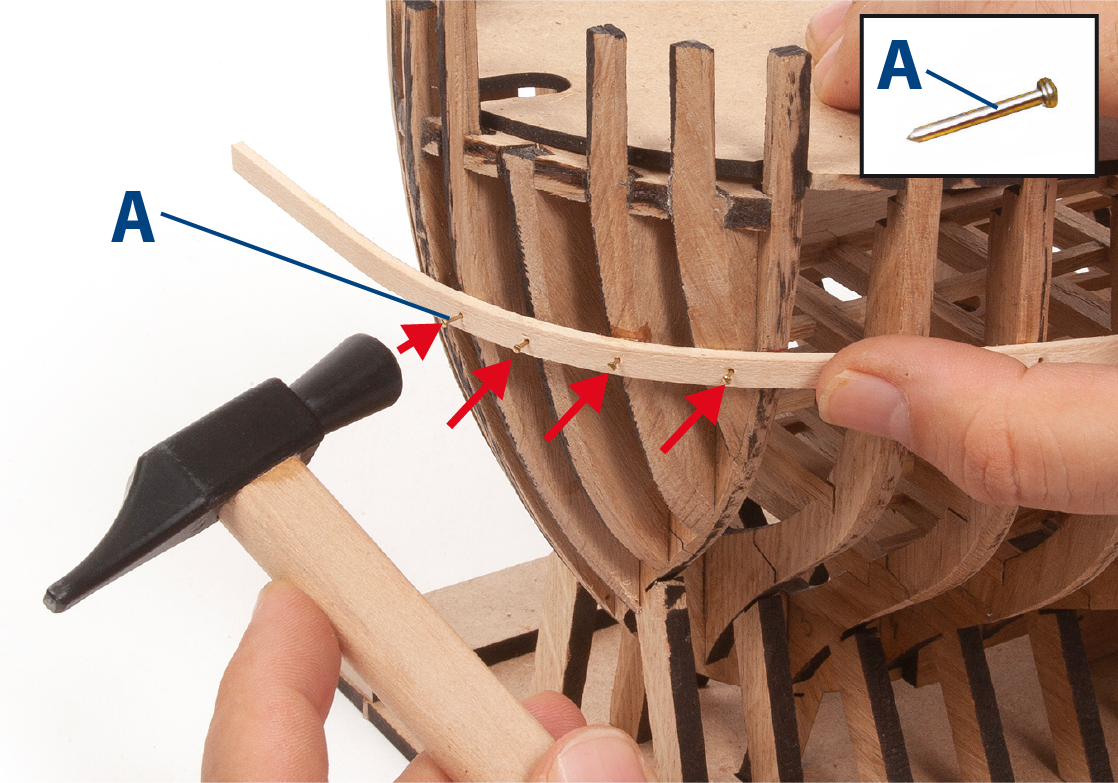

| Nail (A) | 1000 |

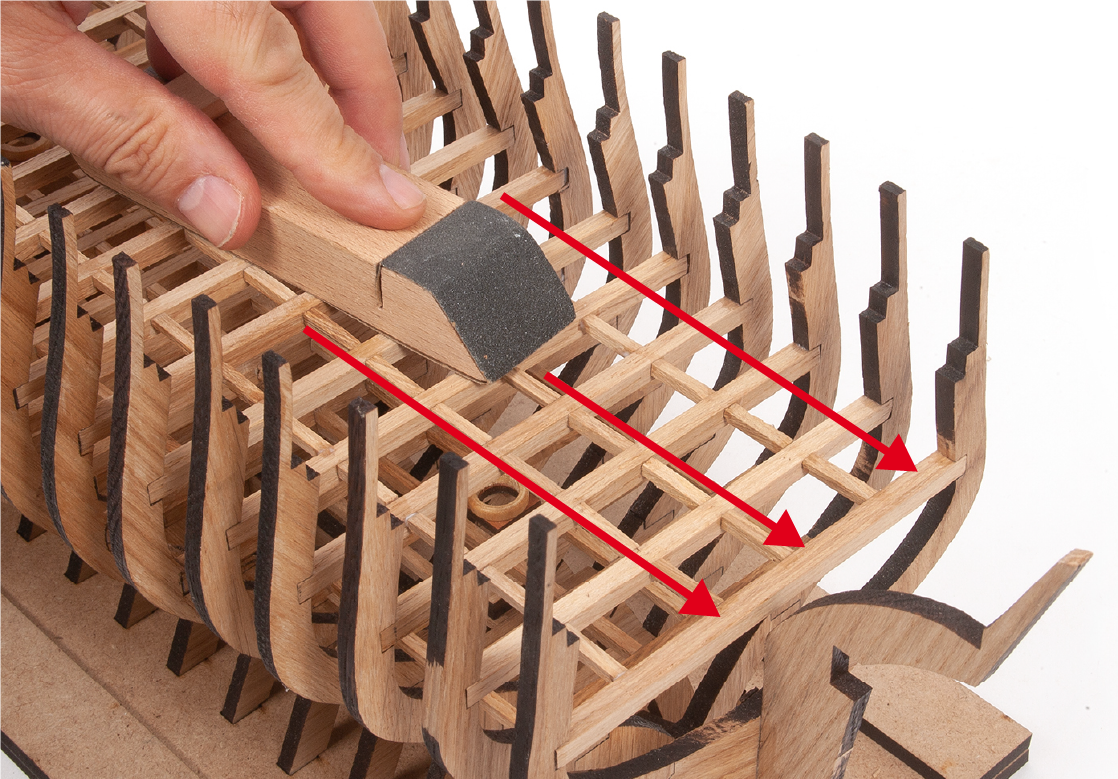

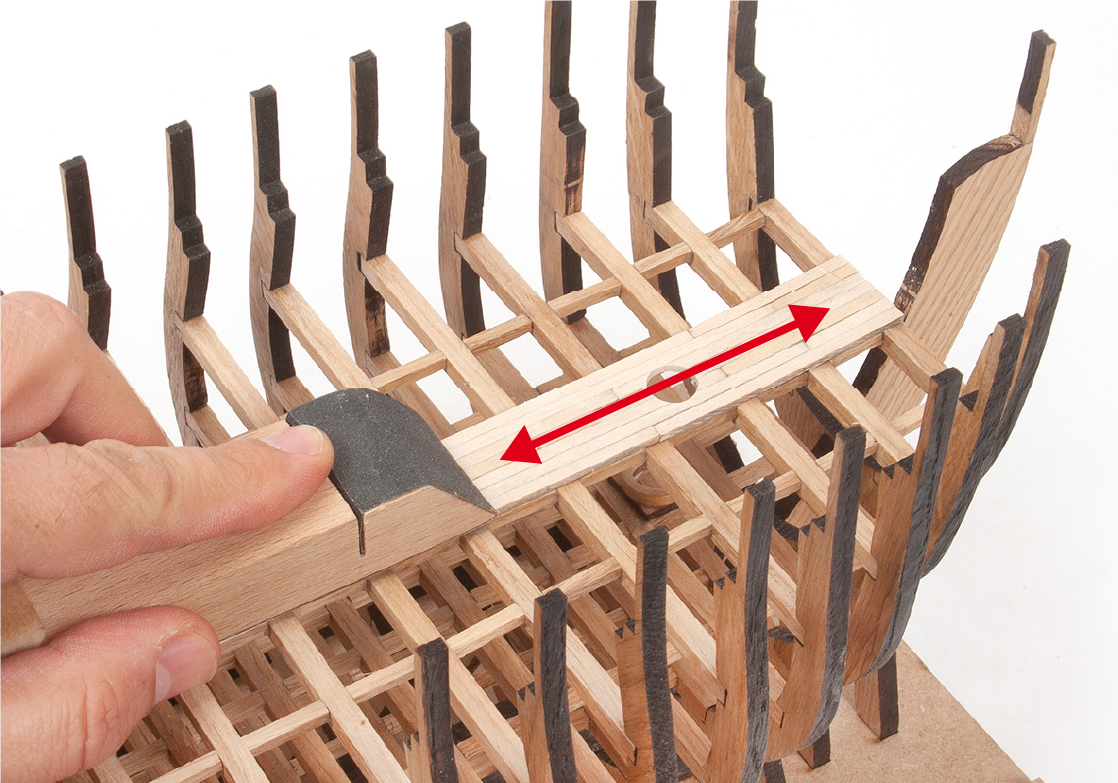

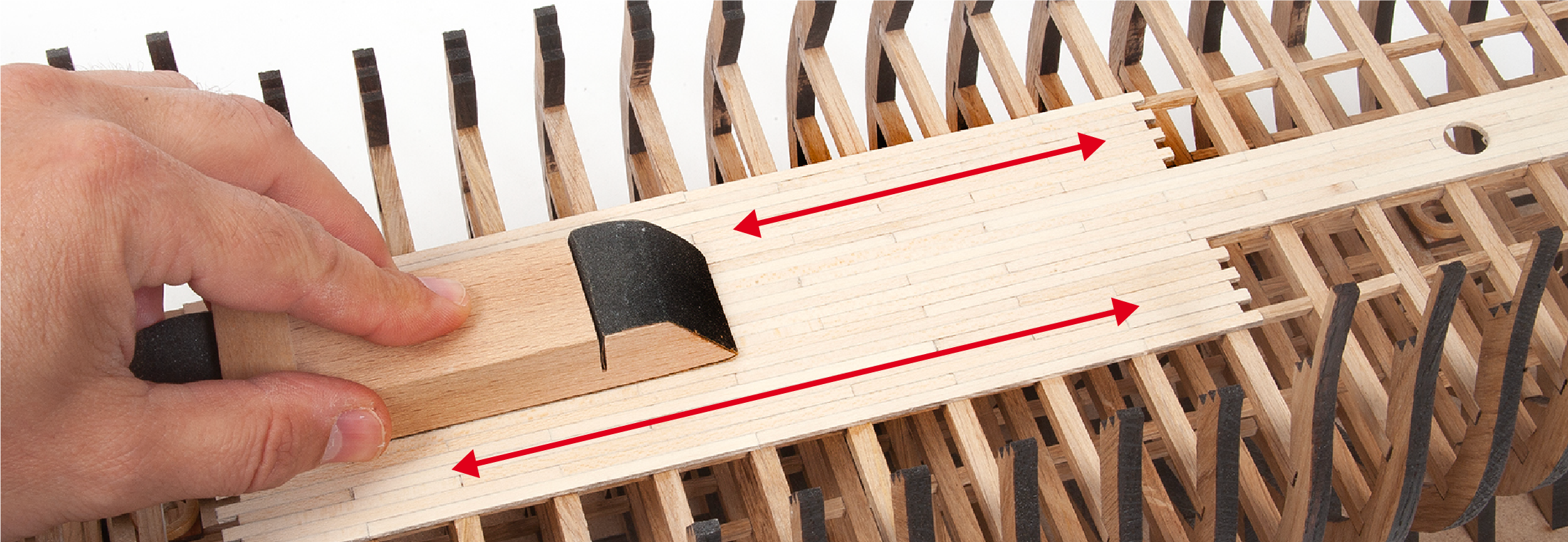

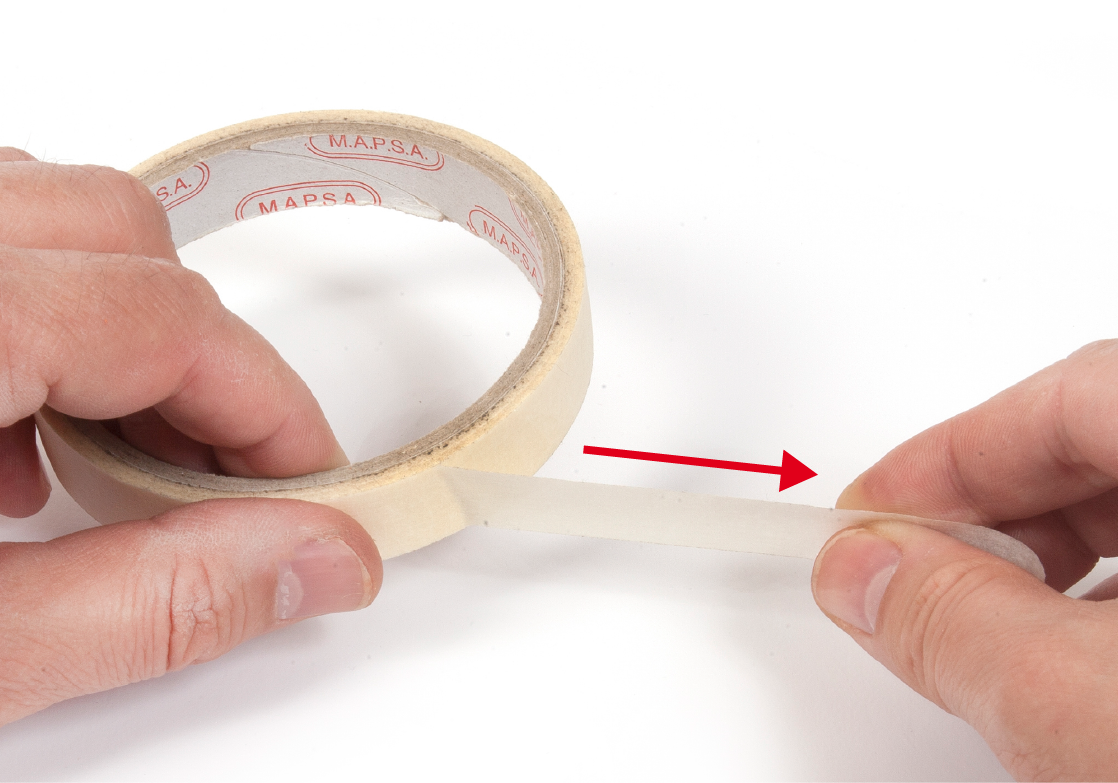

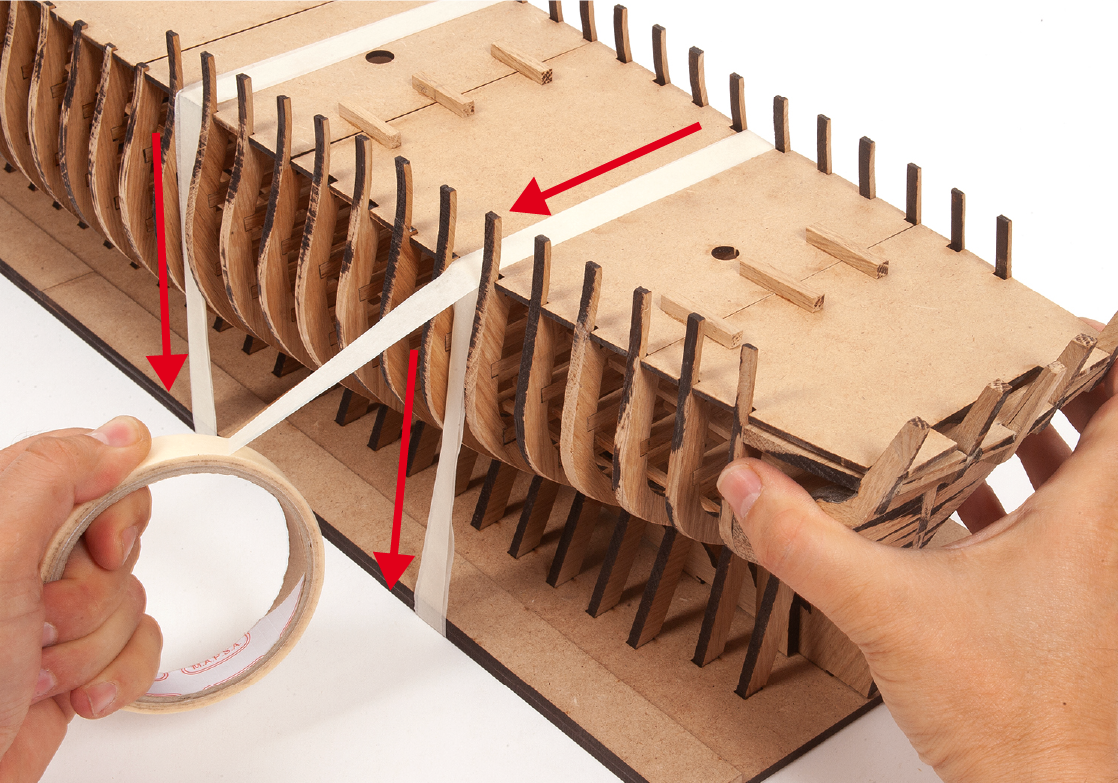

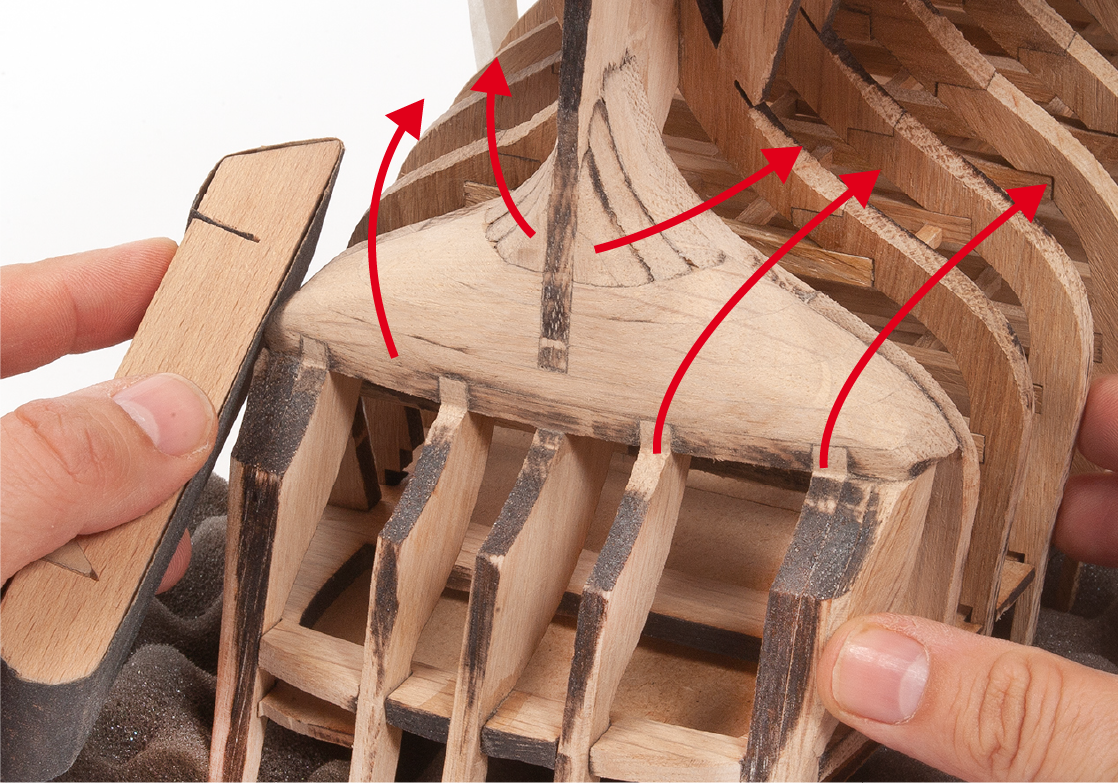

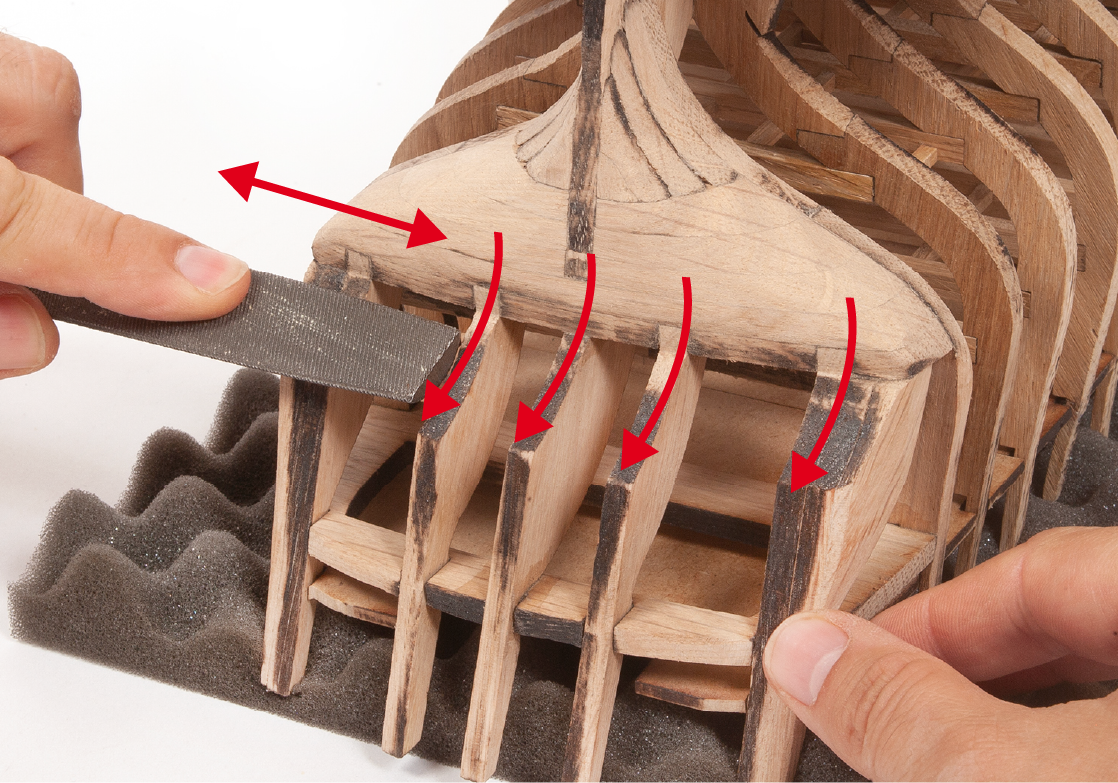

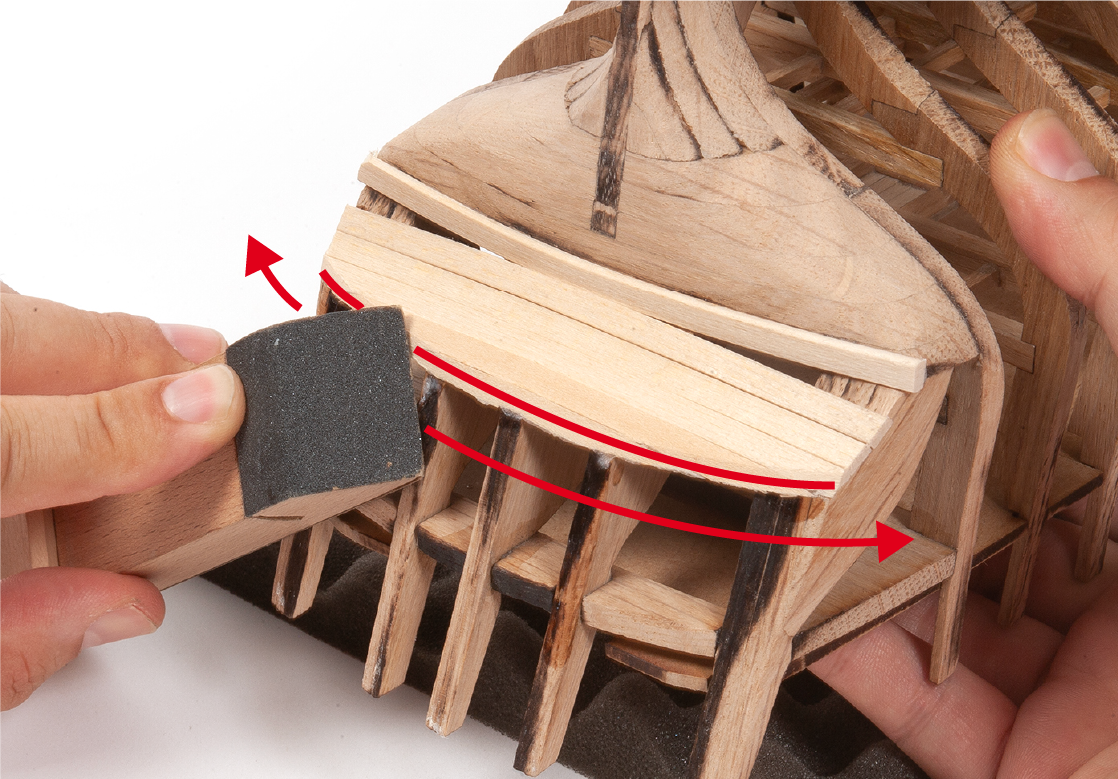

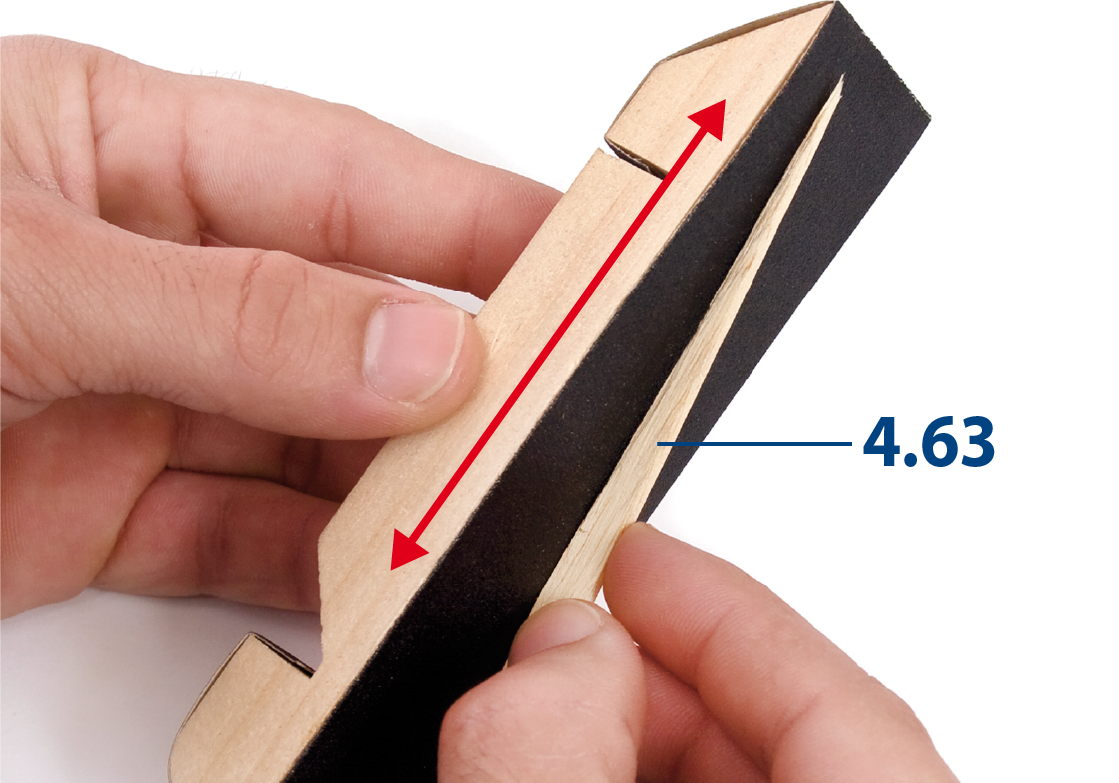

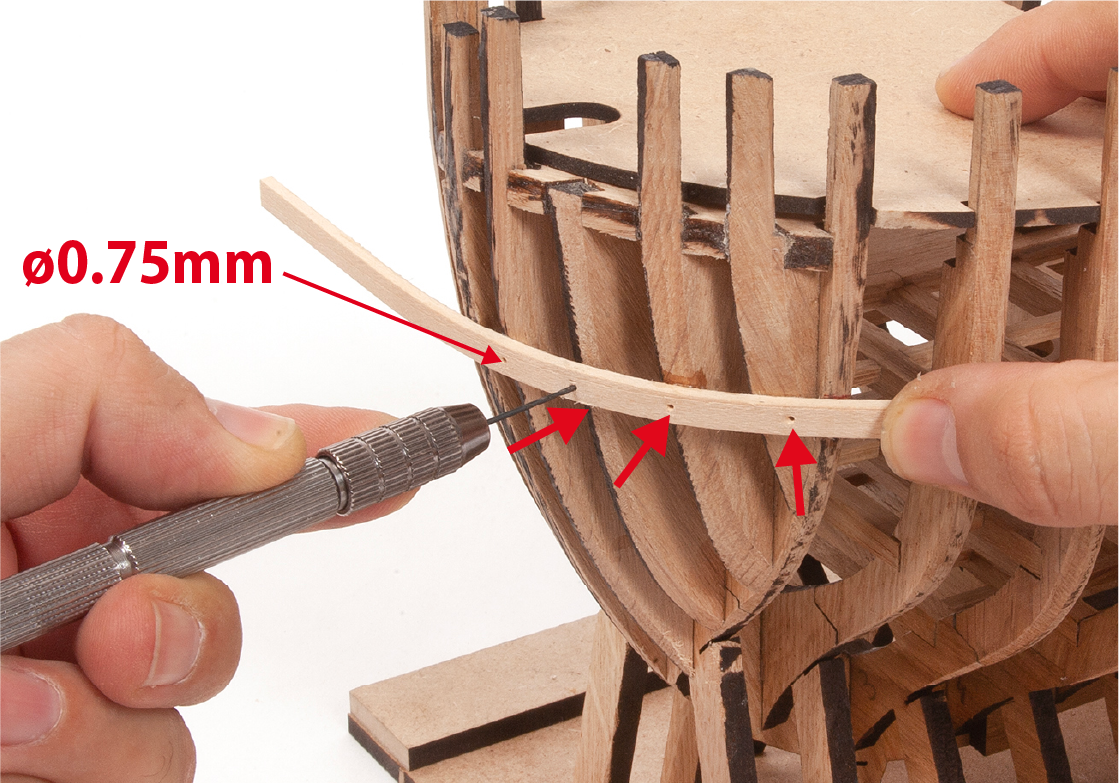

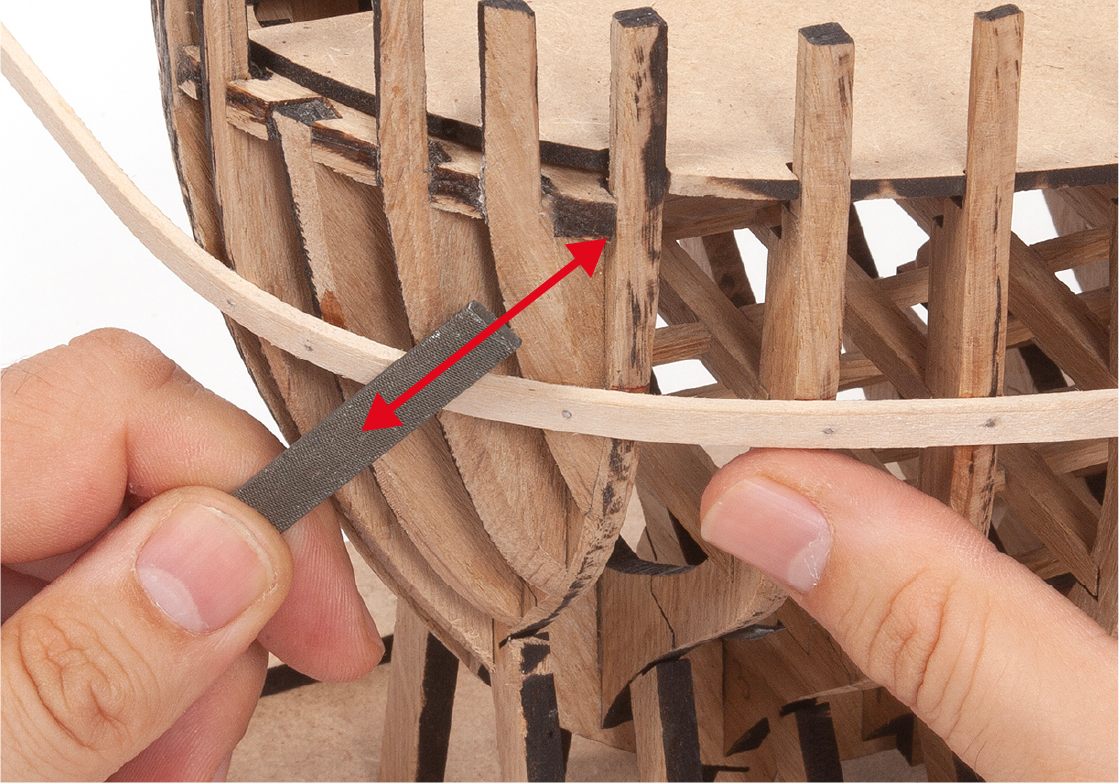

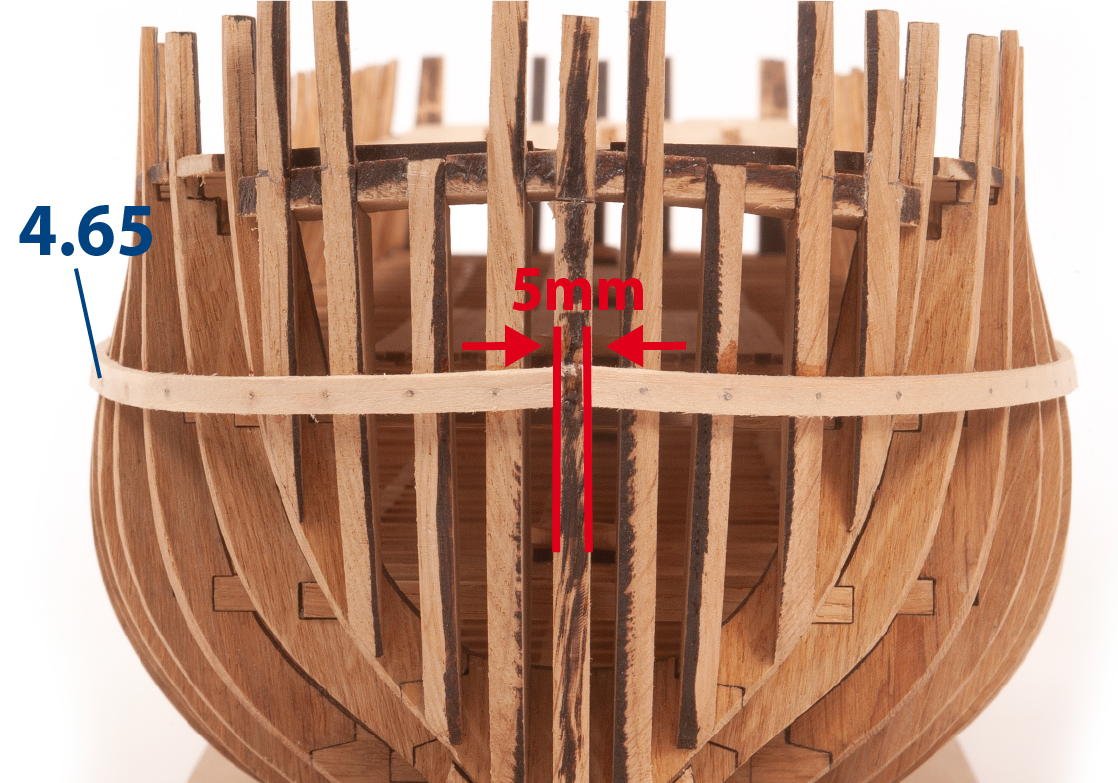

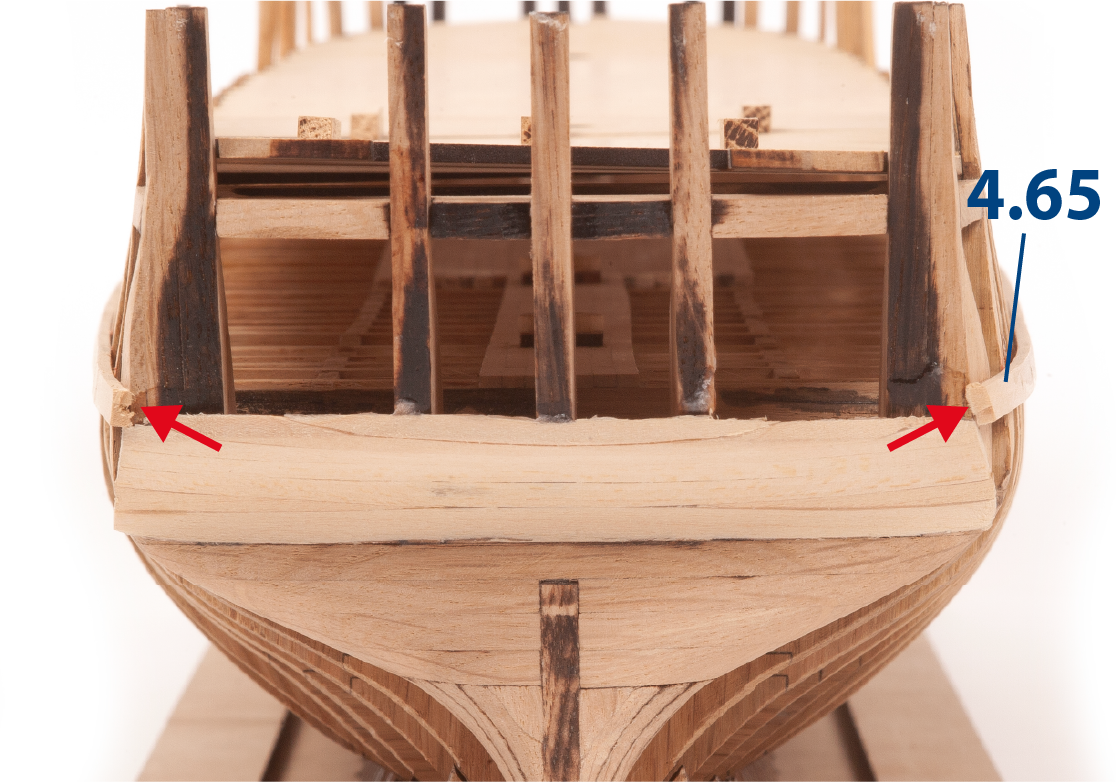

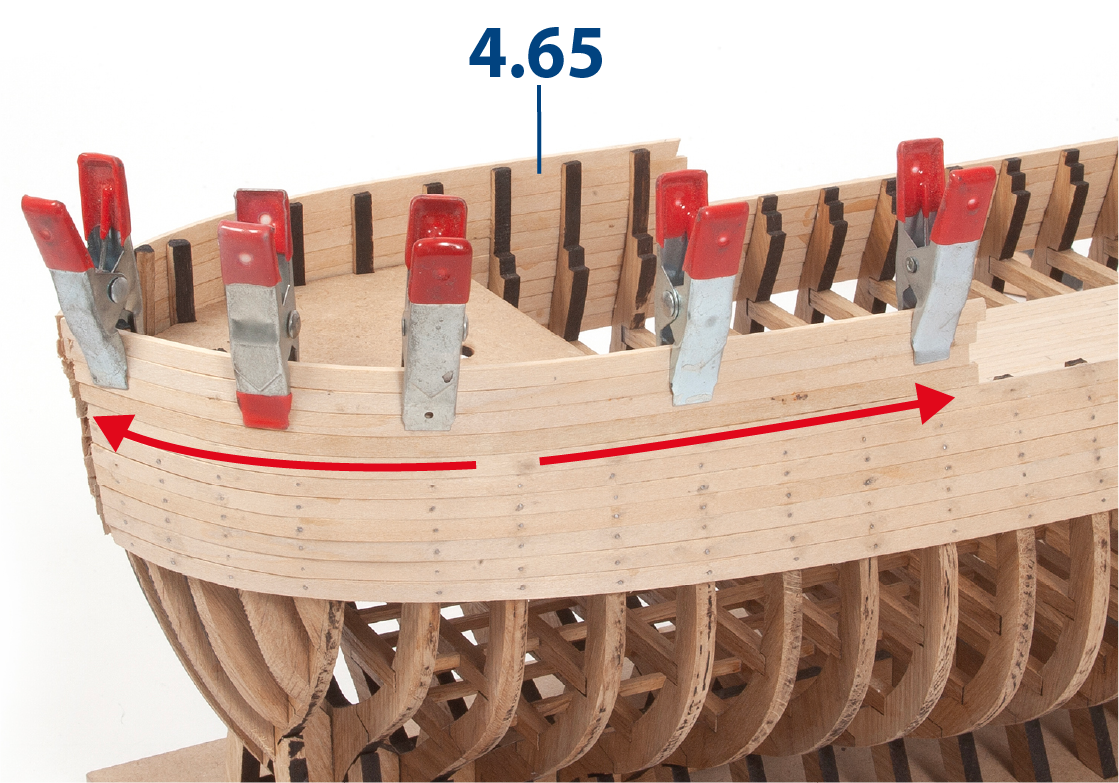

Tools you will need: cutting mat, pencil, cutting knife, fine-grit sandpaper or sponge sandpaper, file, white wood glue, super glue (cyanoacrylate glue), masking tape, set square, hacksaw, sanding block, 30 cm steel ruler, clamps, drill, moulding scriber tool

PACK 04 IDENTIFICATION SHEETS

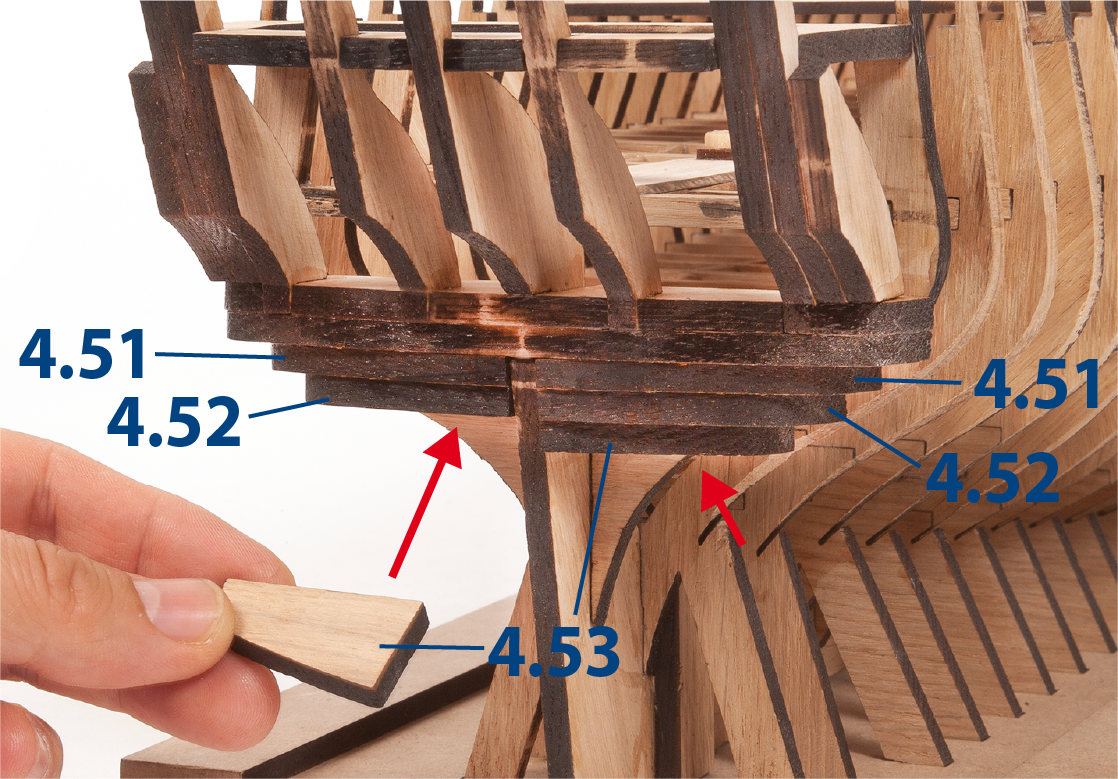

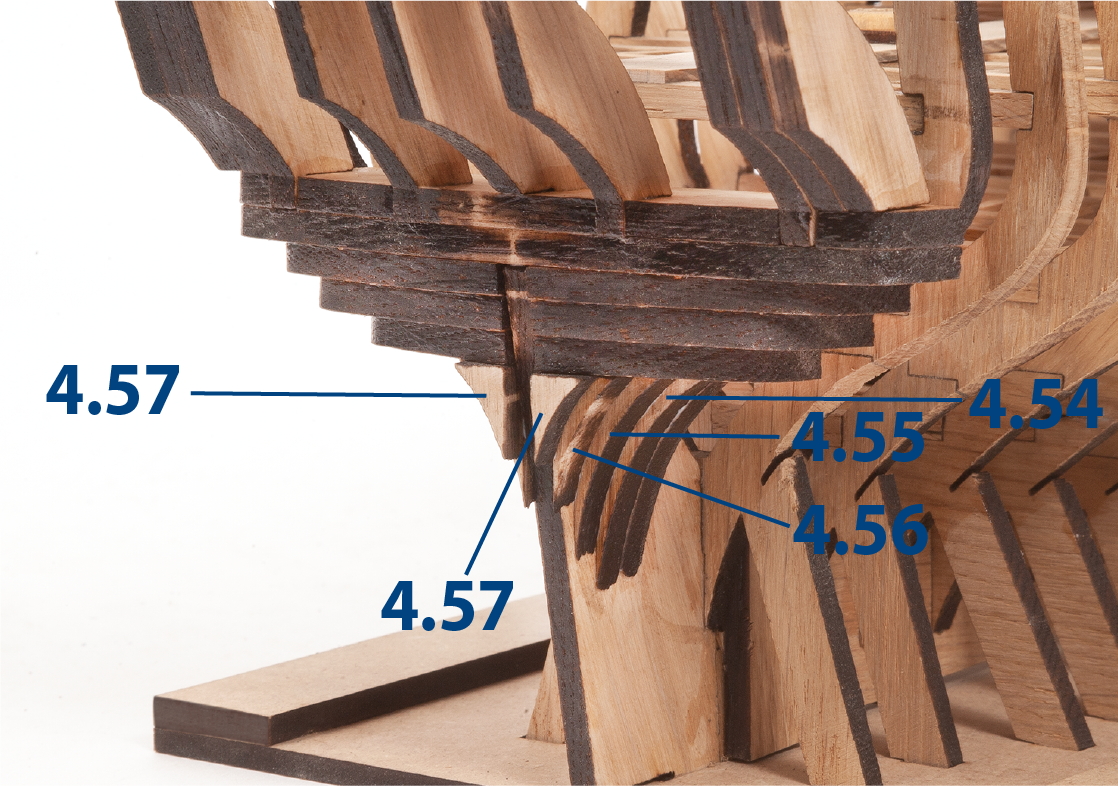

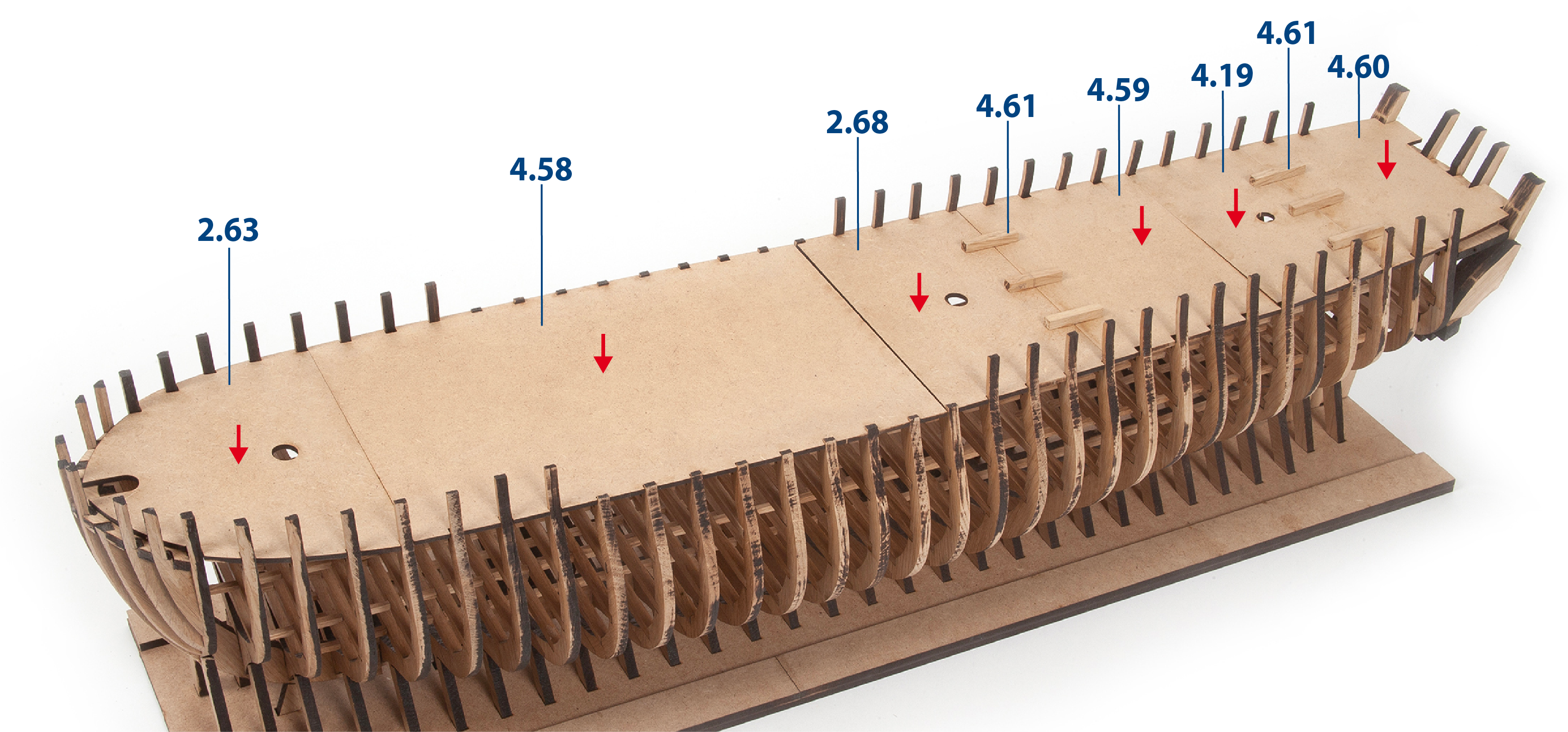

PARTS REFERENCE

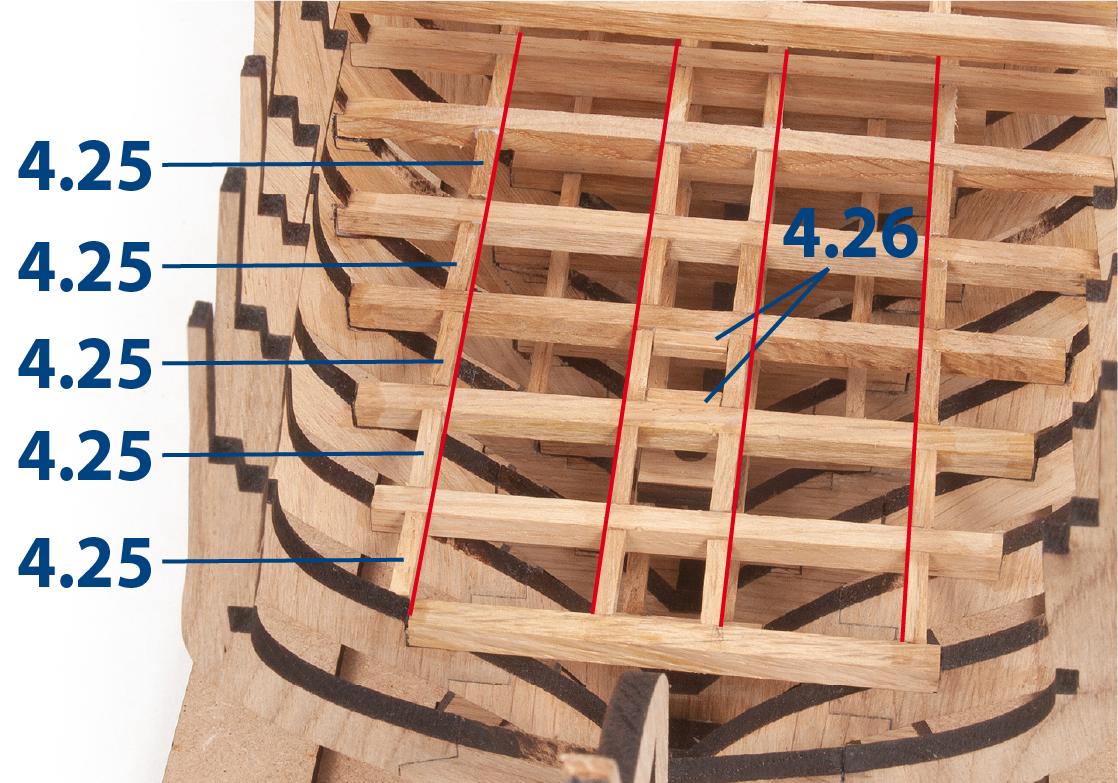

PART NO. | IP-SHEET LOCATION | PART NO. | IP-SHEET LOCATION | PART NO. | IP-SHEET LOCATION |

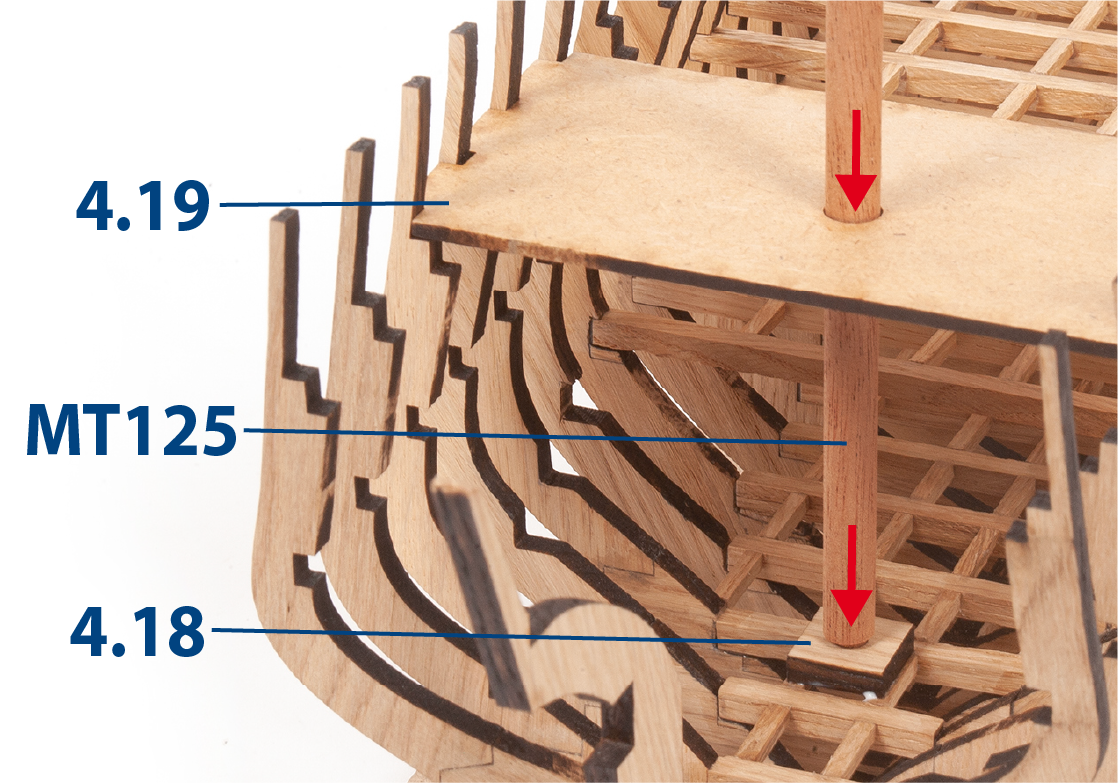

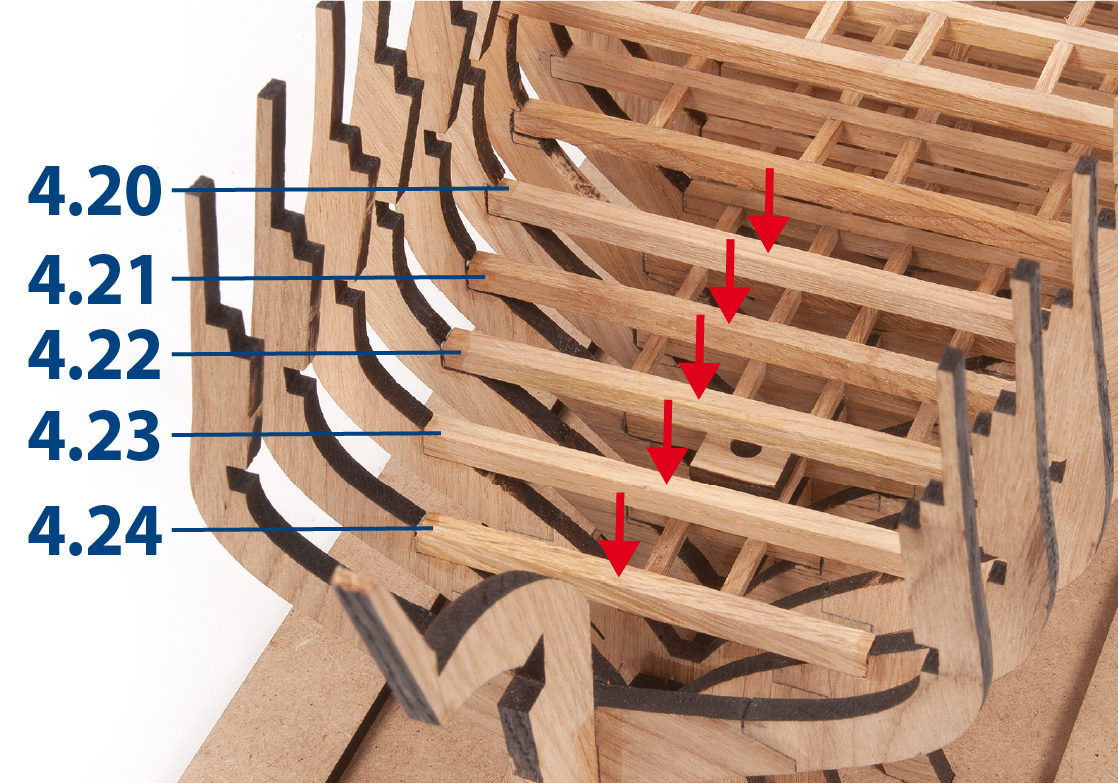

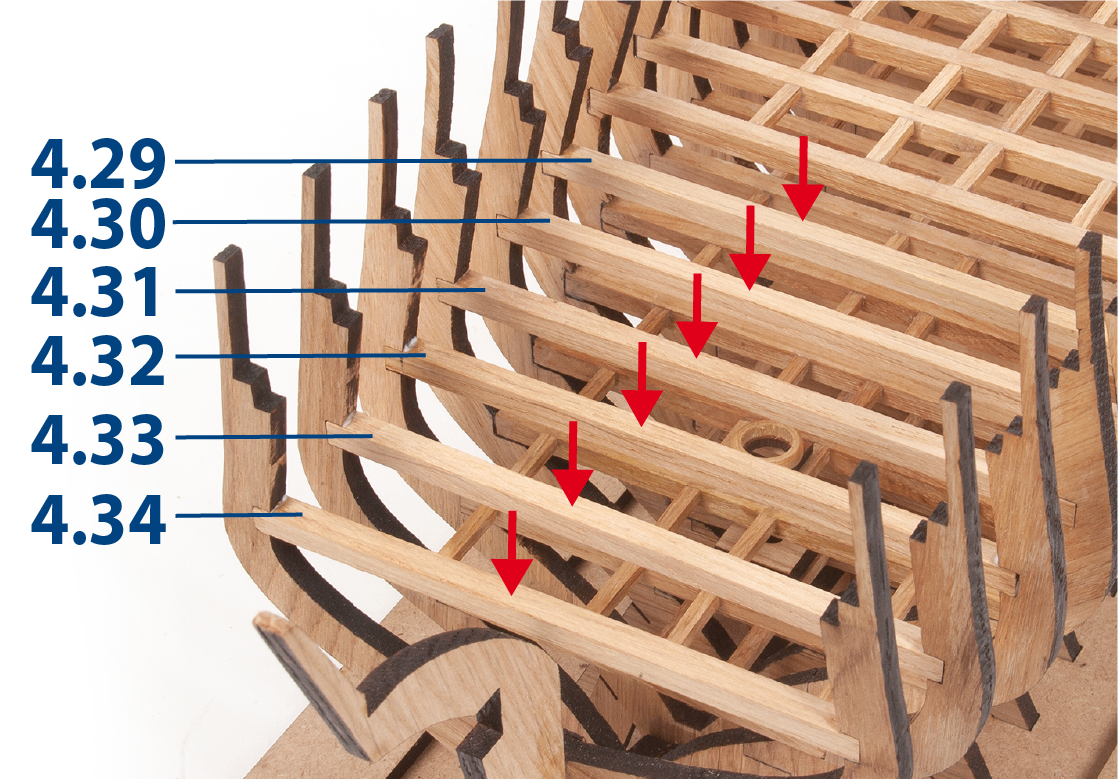

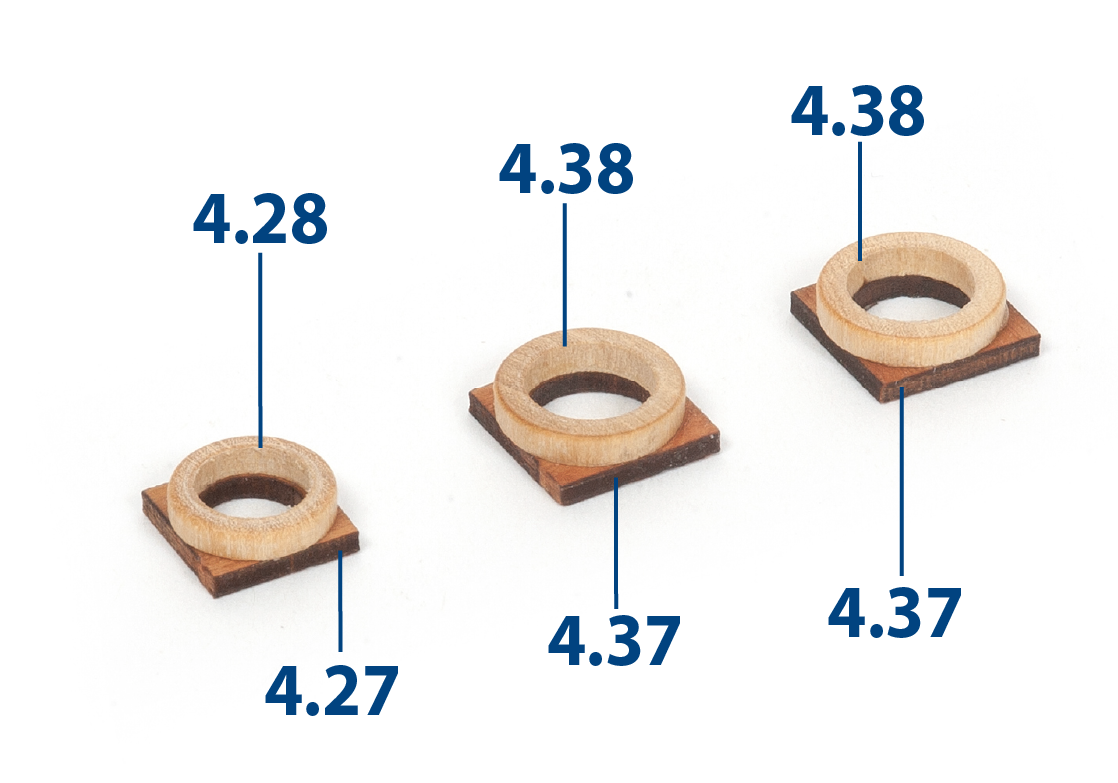

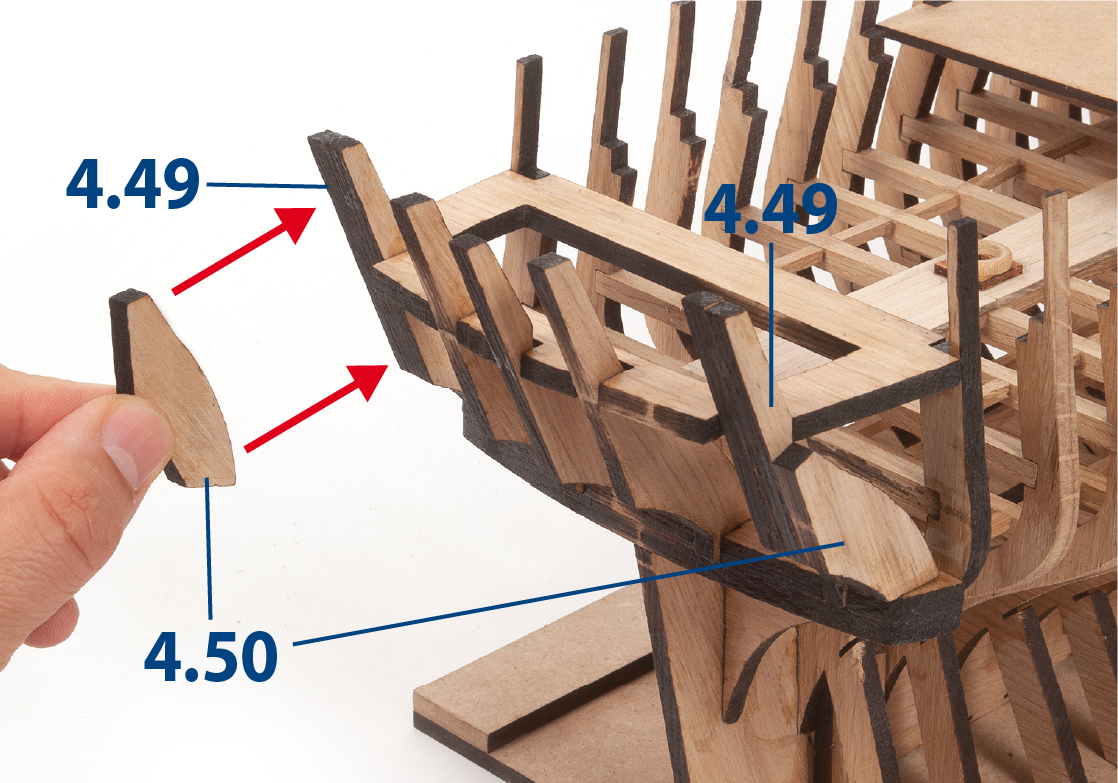

| 4.1 | 2001-17 | 4.19 | 2001-12 | 4.49 | 2001-36 |

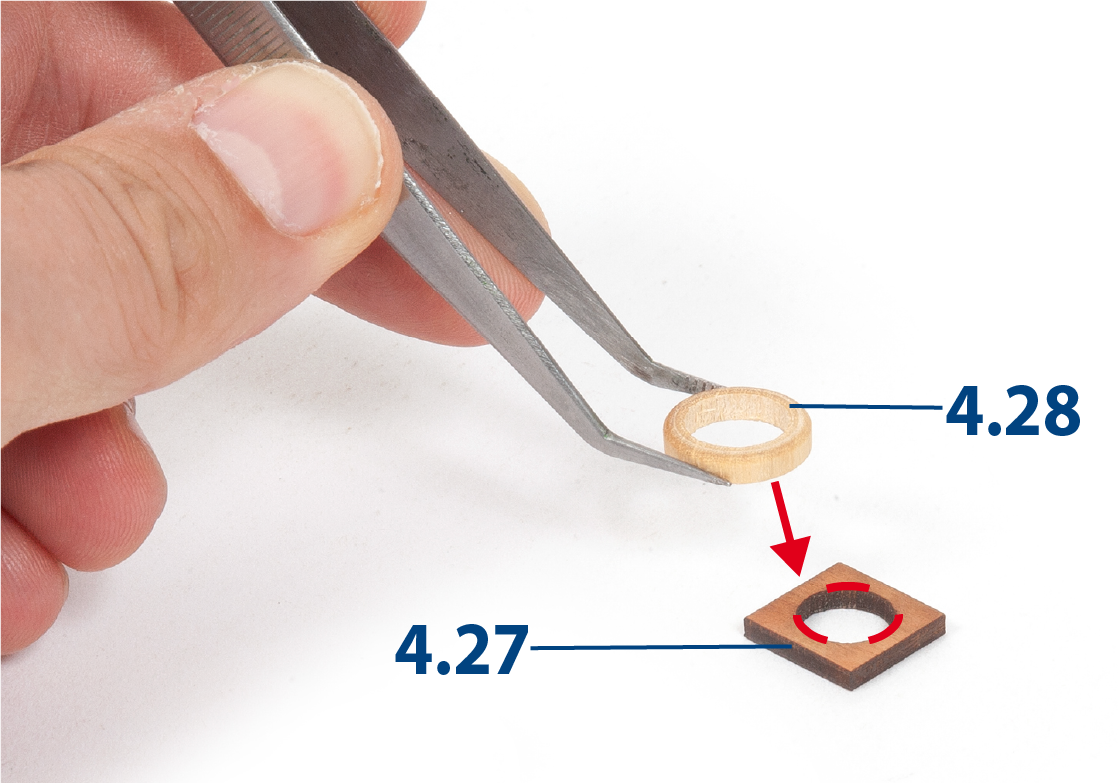

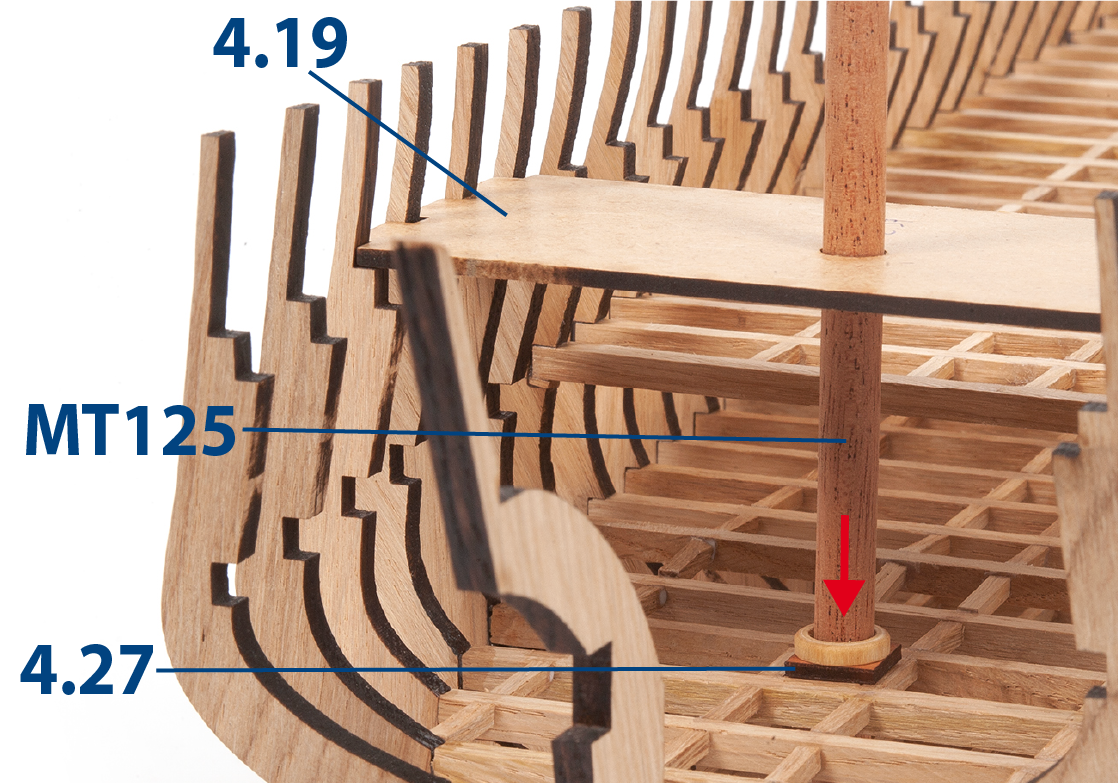

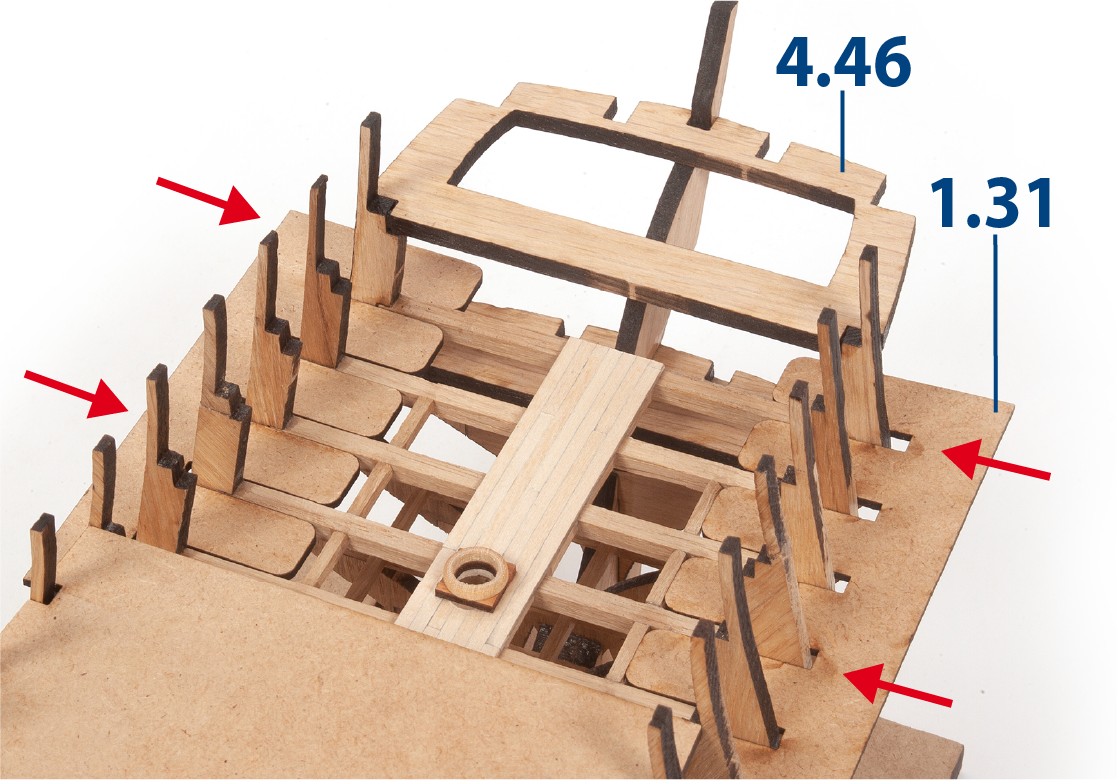

| 4.2 | 2001-18 + 2001-35 | 4.27 | 2001-11 | 4.50 | 2001-6 + 2001-36 |

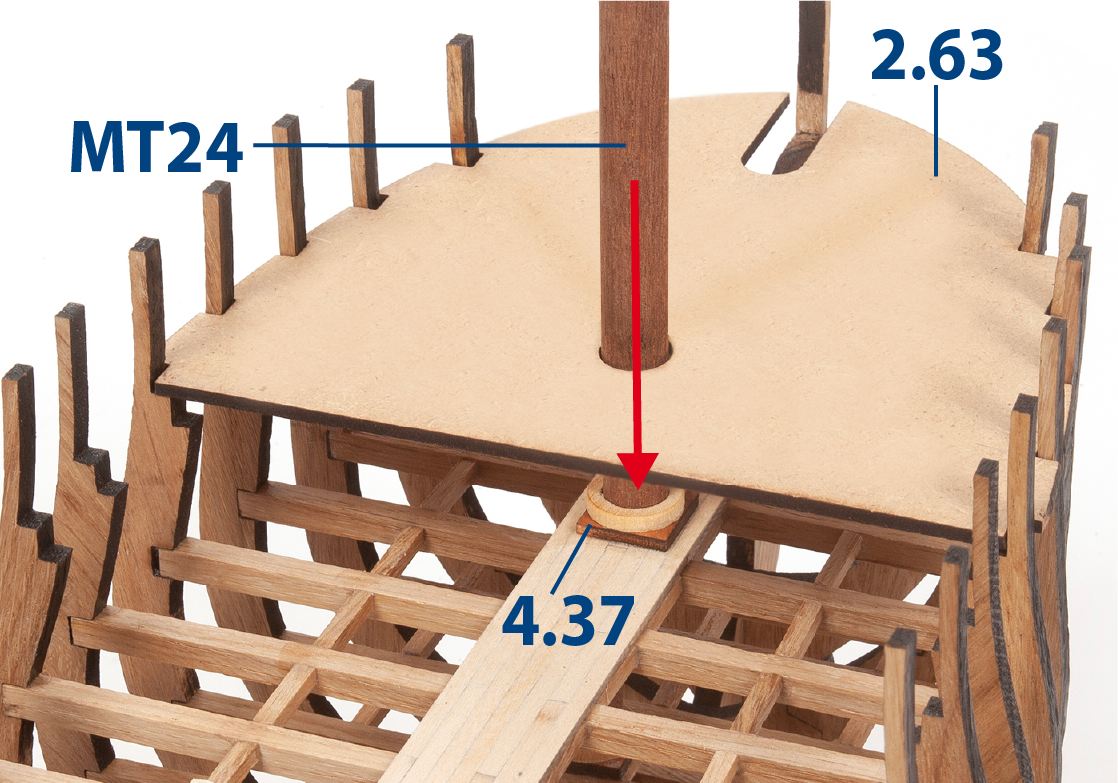

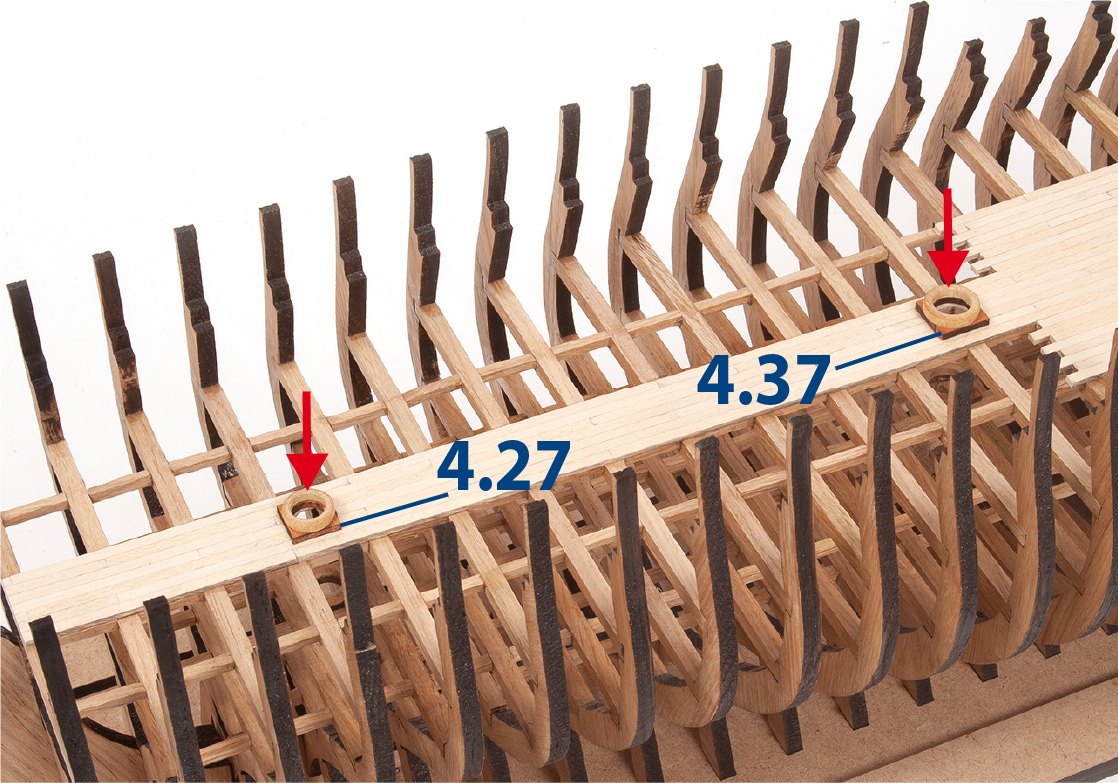

| 4.3 | 2001-18 | 4.37 | 2001-11 | 4.51 | 2001-6 + 2001-8 |

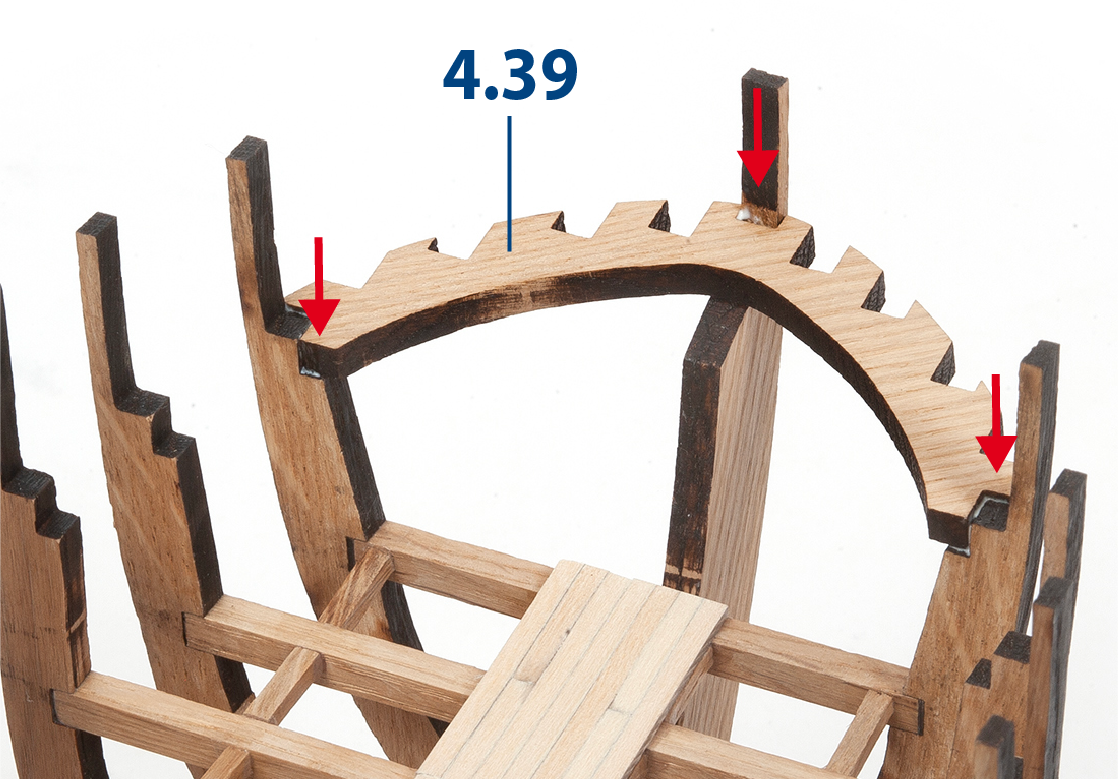

| 4.4 | 2001-35 | 4.39 | 2001-10 | 4.52 | 2001-2 |

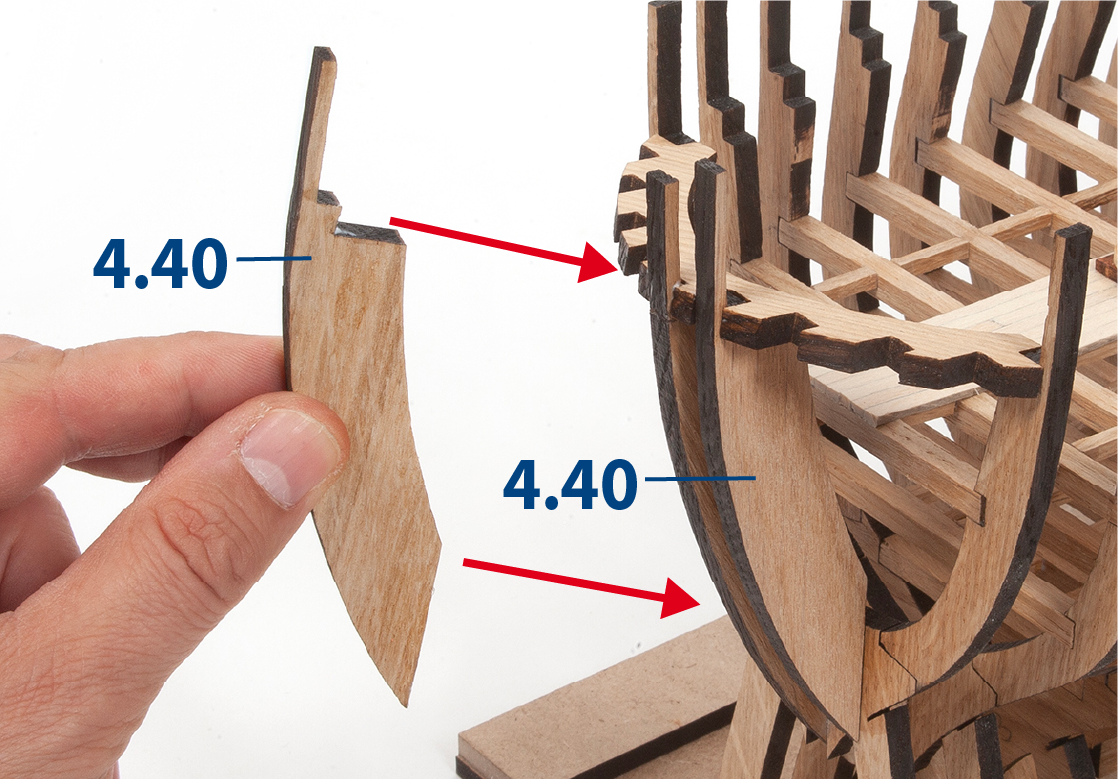

| 4.5 | 2001-18 | 4.40 | 2001-2 + 2001-36 | 4.53 | 2001-6 |

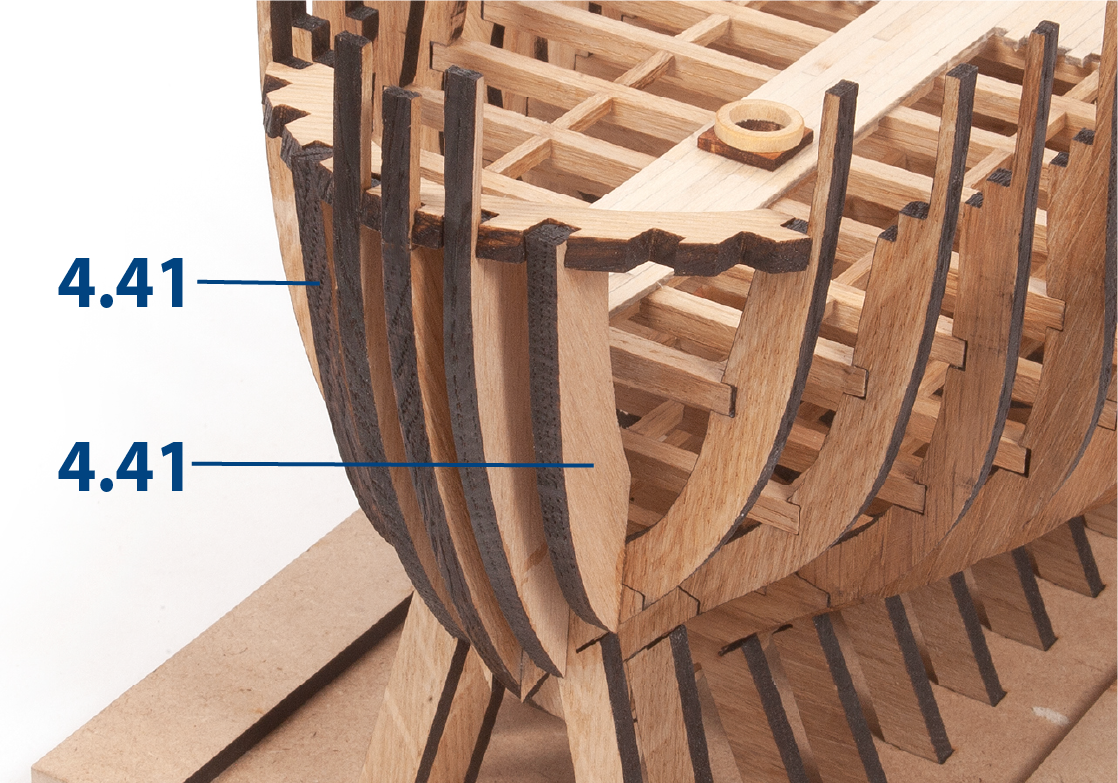

| 4.6 | 2001-35 | 4.41 | 2001-2 + 2001-10 | 4.54 | 2001-15 |

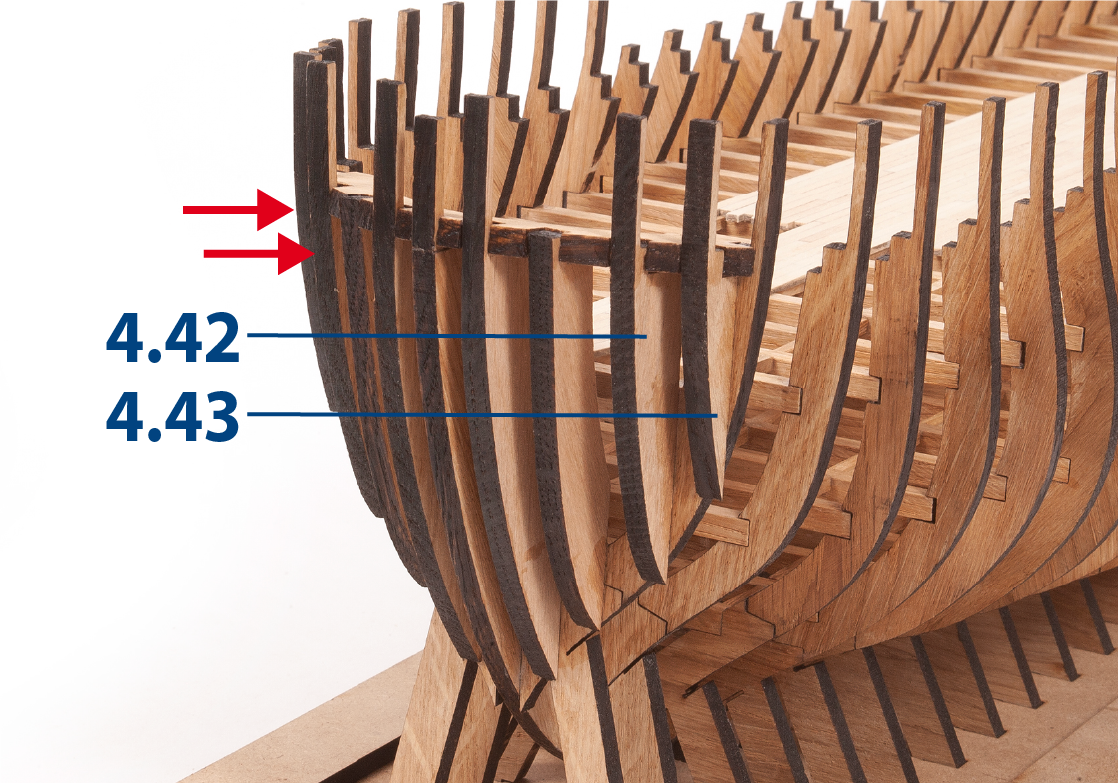

| 4.7 | 2001-35 | 4.42 | 2001-2 + 2001-36 | 4.55 | 2001-15 |

| 4.8 | 2001-35 | 4.43 | 2001-2 + 2001-19 | 4.56 | 2001-8 |

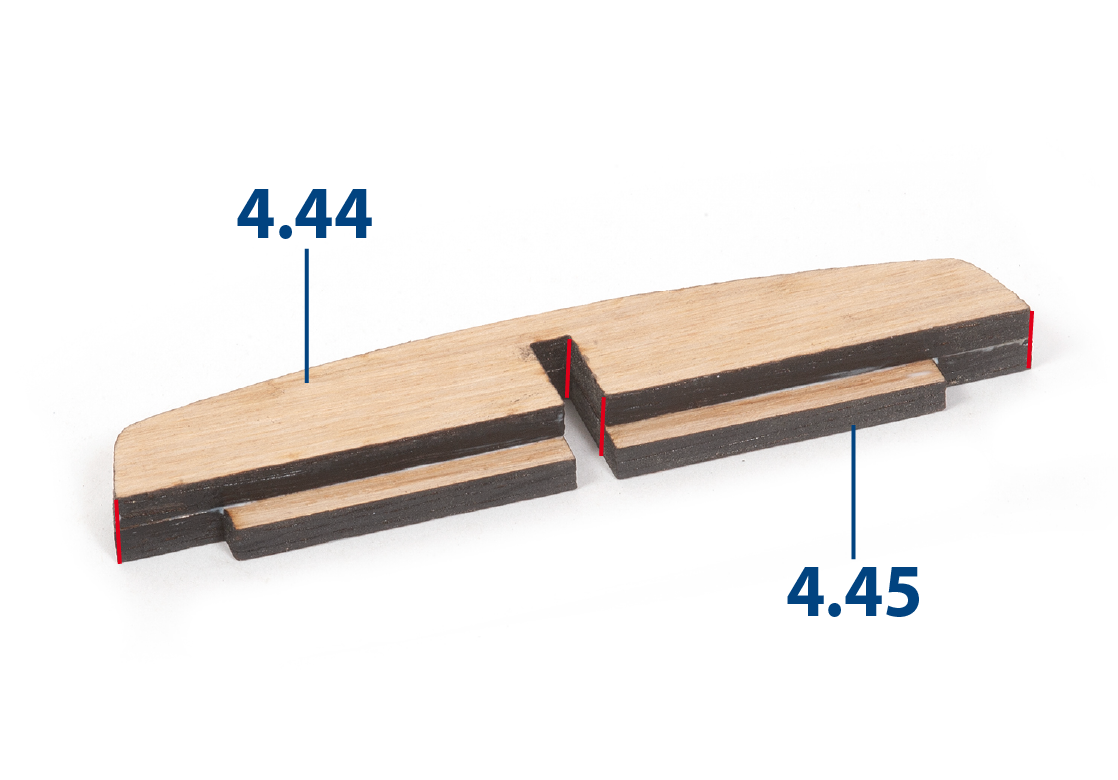

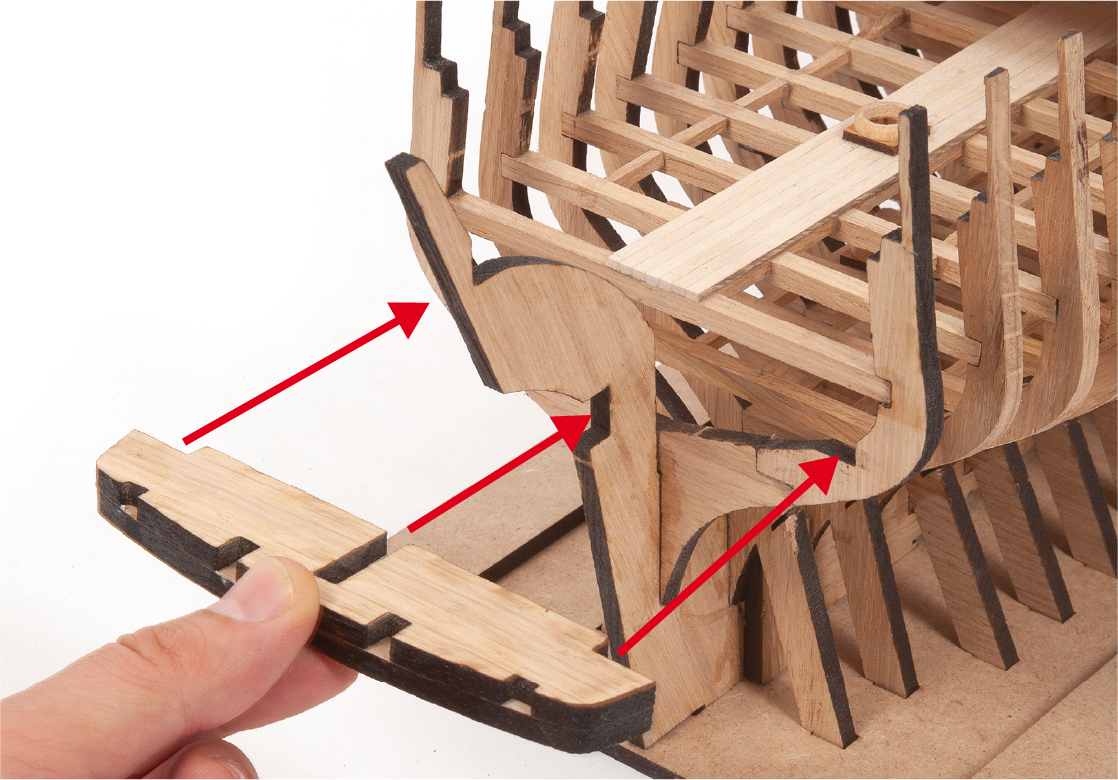

| 4.9 | 2001-35 | 4.44 | 2001-1 | 4.57 | 2001-8 |

| 4.10 | 2001-36 | 4.45 | 2001-1 | 4.58 | 2001-34 |

| 4.11 | 2001-36 | 4.46 | 2001-36 | 4.59 | 2001-34 |

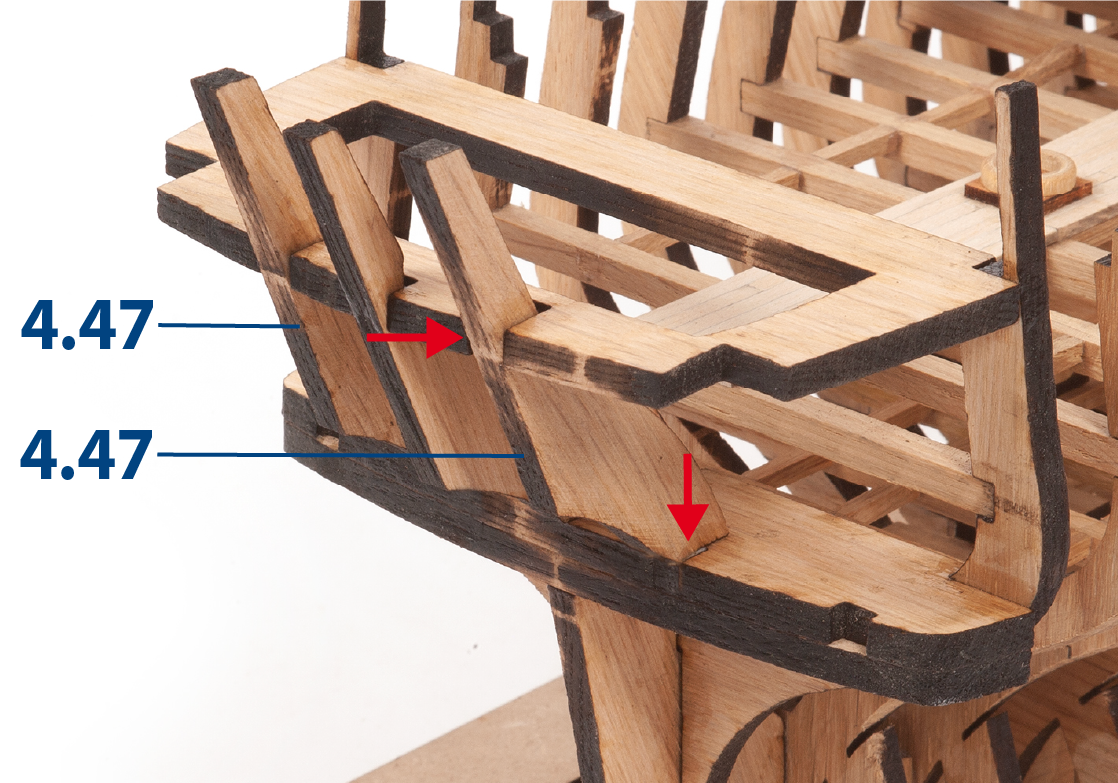

| 4.12 | 2001-36 | 4.47 | 2001-1 | 4.60 | 2001-34 |

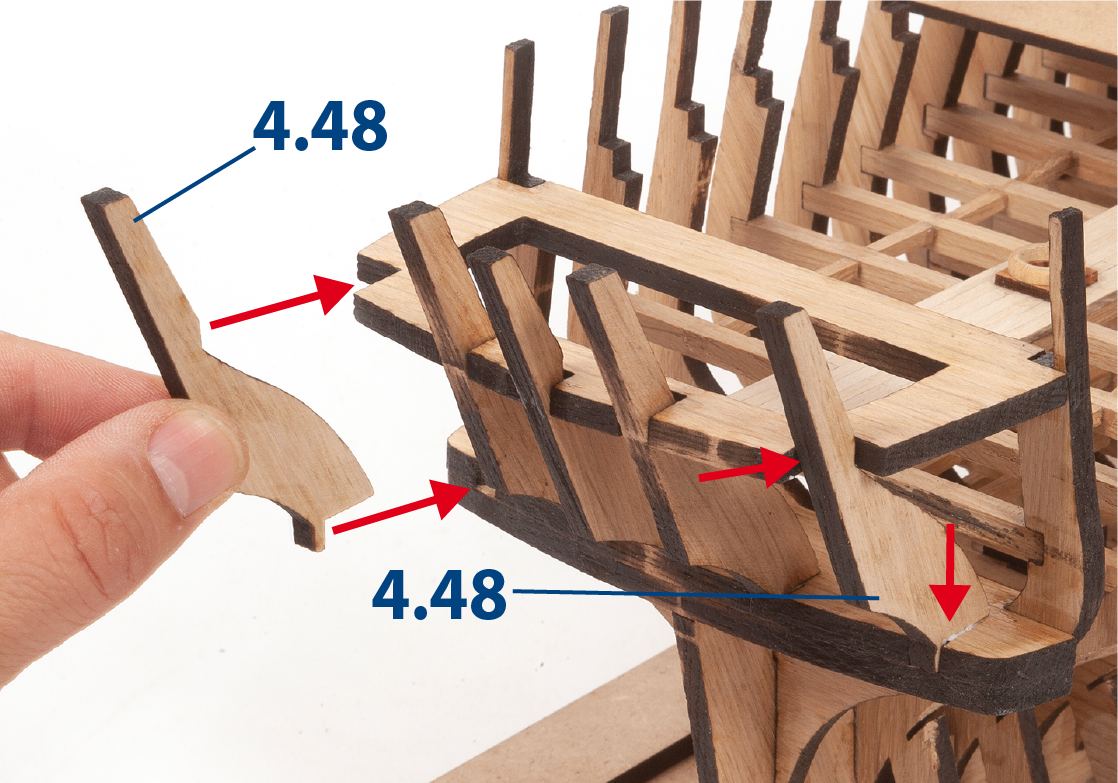

| 4.18 | 2001-35 | 4.48 | 2001-16 + 2001-36 | 4.64 | 2001-5 |