How does Agora Create Such Accurate Models?

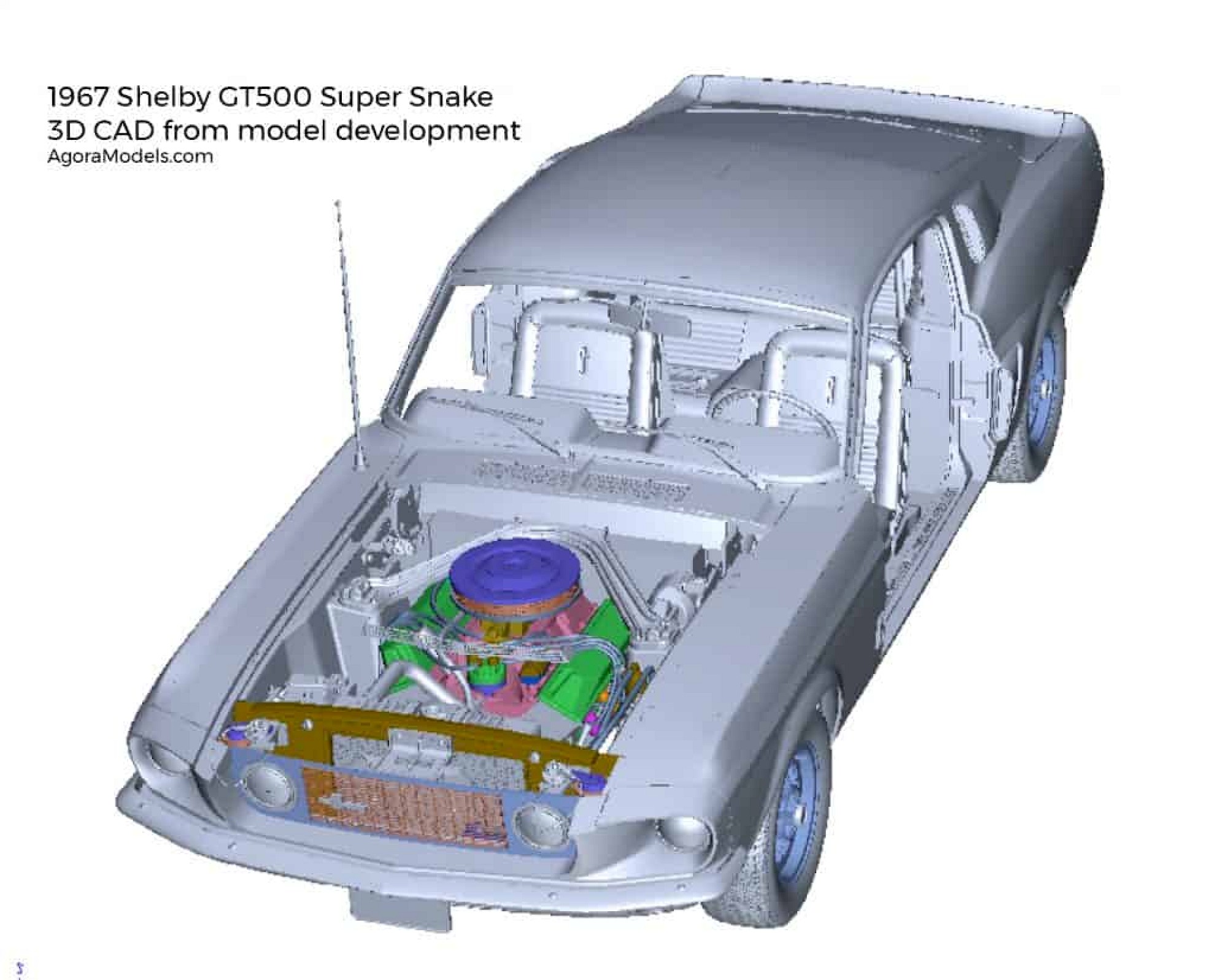

Creating an Agora Model car is no mean feat, and it all begins with the scanning of the original.

We use 3D optical measurement industry experts Physical Digital, who in turn use the best-quality equipment and software. In fact, they are the world’s first company to have been awarded a Nadcap (formerly National Aerospace and Defense Contractors Accreditation Program) accreditation for measurement and inspection using 3D Structured Light.

The software used is the market leader which, when not being employed to bring you models like the 1967 GT500 Super Snake, is also utilized in the medical, nuclear and aerospace industries.

In fact, it is the same equipment that is used for checking that satellites are being manufactured correctly – components are scanned, and this scan is then compared to the CAD drawing (which is the ideal version of the component) to check the accuracy of the physical part.

So how does the scanning process actually work? It’s a little more complicated than just running over the car with a hand-held scanner!

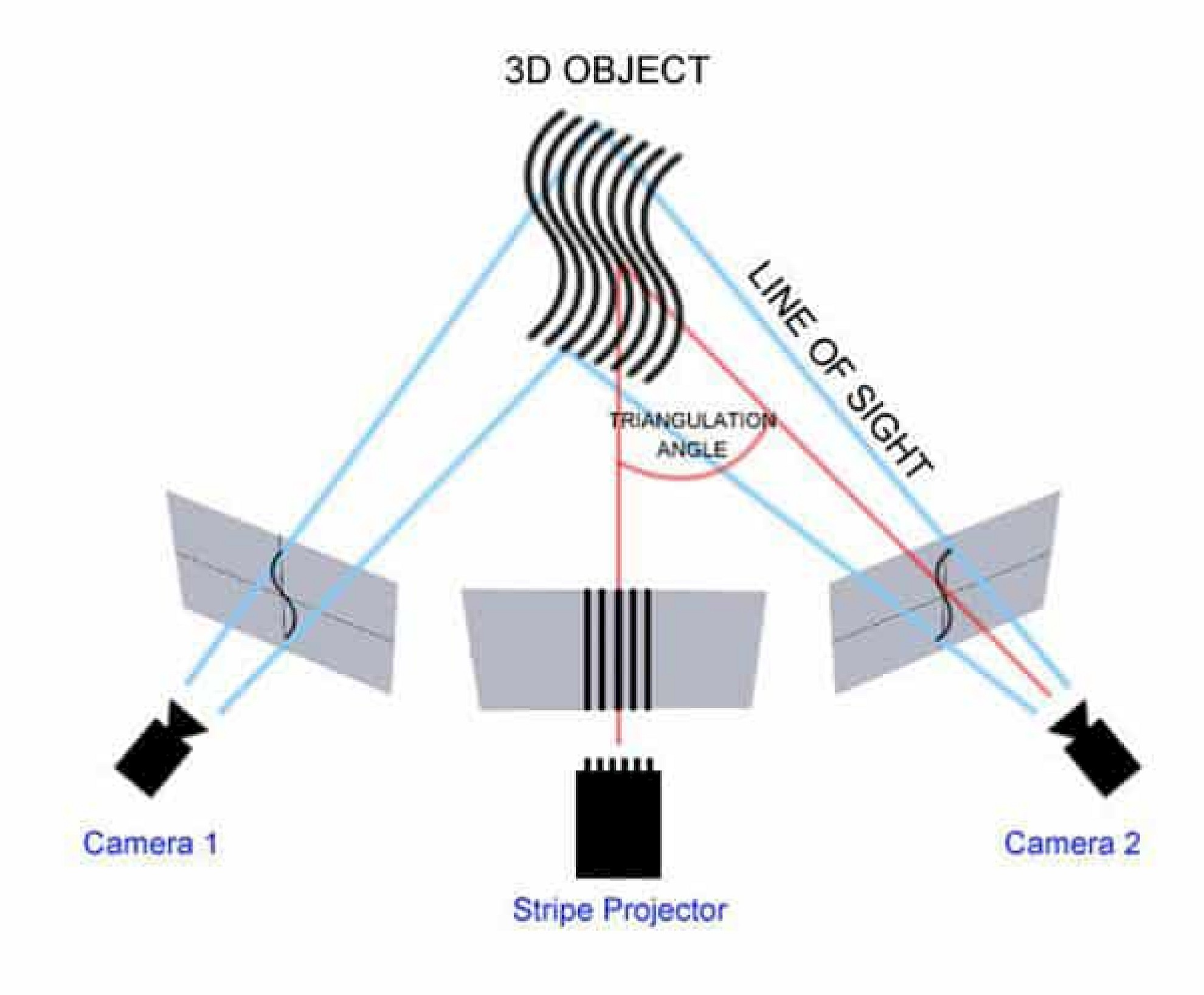

The principle behind 3D scanning.

The method Agora Models uses also employs photogrammetry, in conjunction with scanning, for increased accuracy (credit: smartdesignlabs.com).

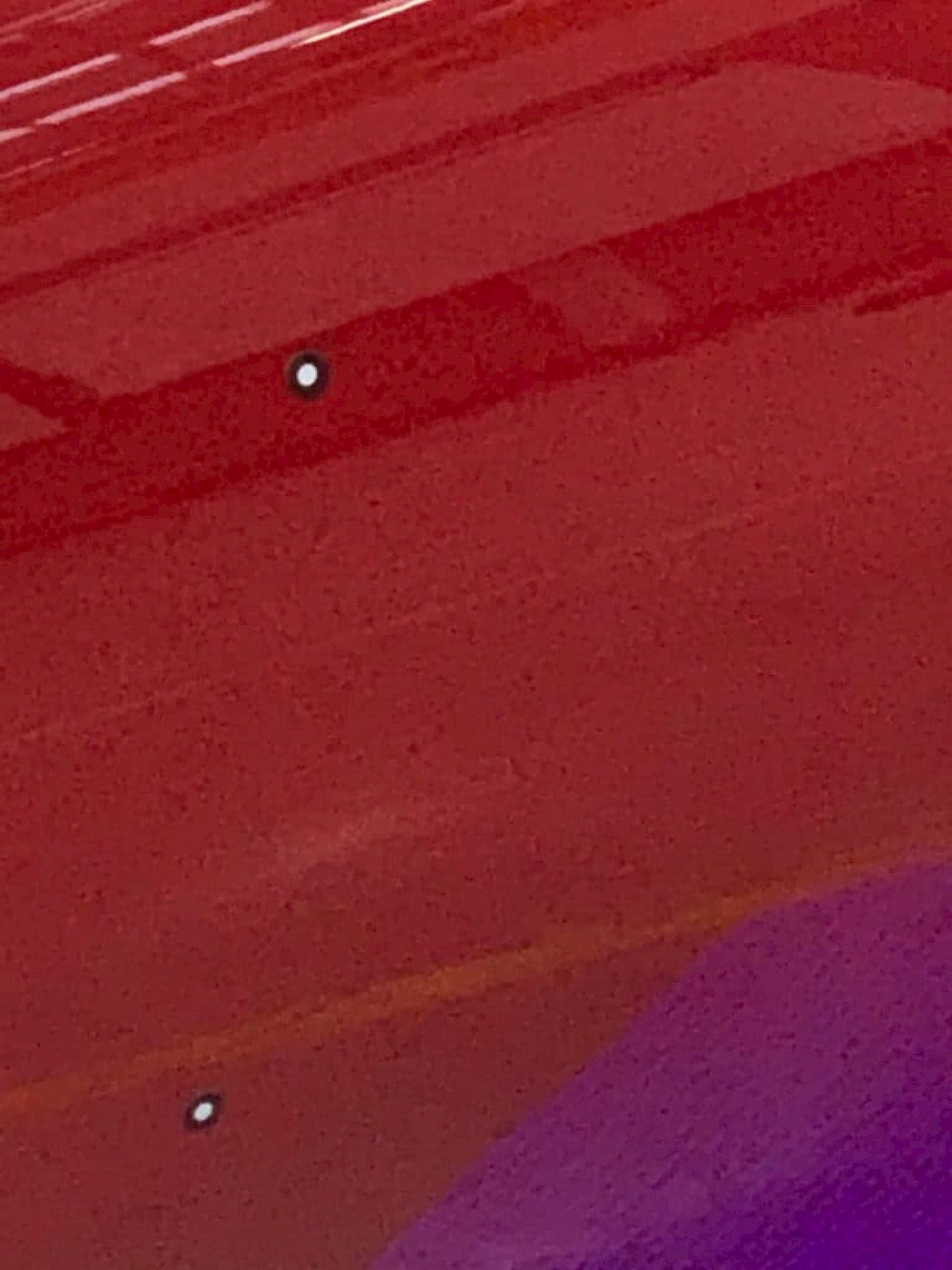

First a series of small target markers are stuck all over the car. These act as points that are initially unknown and uncoded – they simply exist as a yet-to-be-defined point in space.

An example of uncoded target markers affixed to the door of an up-coming Agora Model.

Next, using a DSLR camera, lots of photographs are taken of the car (for our latest project, 100 photographs were taken), but placed in the photo are optical barcodes, which the camera’s software does recognise. Now, by knowing the points of the optical barcode, it can triangulate the position of the unknown points, by looking for the centre of the ellipse on the optical barcode.

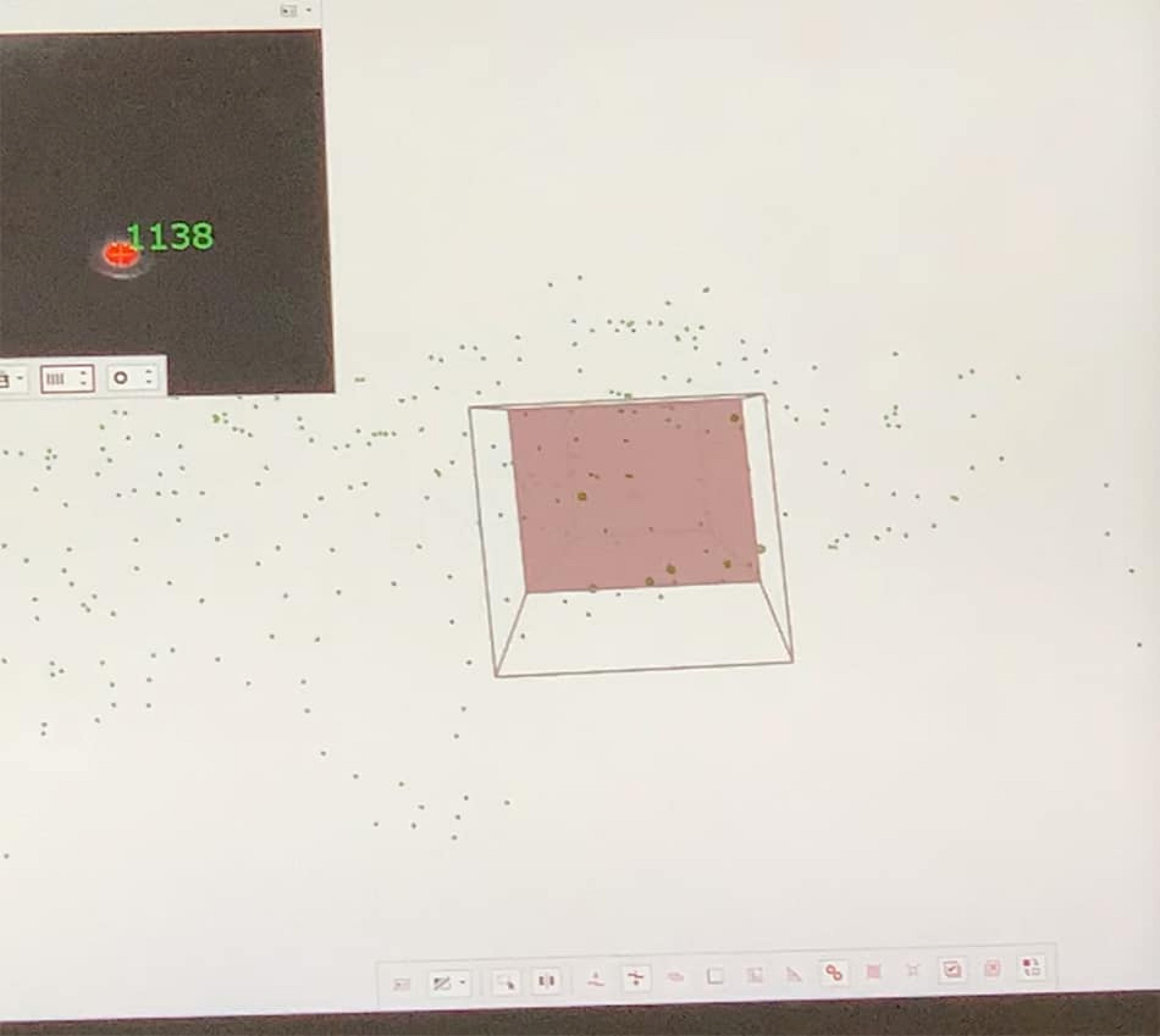

Photogrammetry uses photographs to determine where points are in space, and helps the scanner build up and accurate model.

The optical barcodes on the hood of a car. By using the optical barcodes, the camera can assign codes to the uncoded markers and build up a point cloud of the car.

Optical barcodes or coded target markers are recognized by the camera’s software (credit above 3 images: physicaldigital.com).

Now that the points are fixed in space and known, the car is then scanned.

Once the scanner can see a minimum of three reference points, it knows exactly which part of the cart it is sensing, by triangulating the unique pattern that they create.

The scanner then creates a 3D polygon model, by filling in the spaces in between the points. It uses light in a fringe pattern which is essentially strips of blue light. The scanner looks at the contrast between the blue and black lines created by the pattern, since the object (i.e. the car) will distort the light as it passes across the object’s surface.

Target points, the small circular stickers on the surface here, are stuck to the object. The scanner detects the contrast created by the fringe pattern to build up a 3D model. By detecting the targets, and the unique pattern they create, it knows exactly which part of the object it is scanning.

In terms of accuracy, it doesn’t get much better than this.

Most scanners and scanning software don’t use reference points, i.e. they don’t employ photogrammetry as a partner. By doing it this way, the experts Agora use are able to lock all the points in space.

The beauty of this is that the scans are constantly being snapped back to the fixed points, which have been defined by the photographs: they are in constant communication.

When you have a hand-held scanner, without partnering it with photogrammetry, the only feedback you get is back to the scanner itself – you just get a ‘best-fit’.

This causes problems in terms of margin of error.

By using Physical Digital’s expertise, as the car is being scanned, if there is deviation between where the computer model thinks the points are and what the scanner is seeing – a deviation of 50 microns or more (0.05mm) – a warning appears, so any errors are immediately flagged.

Hand-held devices don’t do this. In fact, you get deviation stack. Say you have a 4m-long car, you scan its surface and your deviation error is 20 microns; the deviation is cumulative so by the end you could have a deviation of 0.4mm. Compare this with the deviation using photogrammetry: for one of our most recent projects, the deviation was, on average, 0.05 pixels, or 23 microns, which is 0.023mm total (just under 0.001 inches). *(For comparison the diameter of the average human hair is somewhere between 60 and 90 microns).

Scanning in this amount of detail is not a quick job – 600mm3 are scanned at time – and there can be challenges. Interiors, for example, get a little more complex, with the camera needing at least 500mm of standoff to be able to pick up the surface data.

So, getting as many different angles as possible is key.

Building up a 3D model on screen – this is how one of our scans starts on a computer screen beginning a highly-accurate model.

Also, the fact the scanner is a light-based measuring tool means that it is affected by surface texture.

Shiny cars reflect light straight back, so a special polish needs to be applied to take some of the reflectivity away.

Some of the Agora team were recently present for the scan of a 1960s car (soon to be an Agora Model!) and its red paintwork made this slightly more problematic since the scanner uses blue light (blue light doesn’t reflect well from a red surface).

The scanning engineers were reluctant to use any kind of polish on the car due to its value and rarity – you’ll have to wait to find out which car it was!

The process is undoubtedly complex, requiring specialist software, hardware and technicians, and takes almost an entire day to scan a single car.

Yet when you consider the accuracy that can be achieved by going the extra mile at the very start of the production process, we believe that it is more than worth it.

At Agora, we use specialists to create scans just like these at the beginning of our model creation.